Pneumatic Press Manufacturer

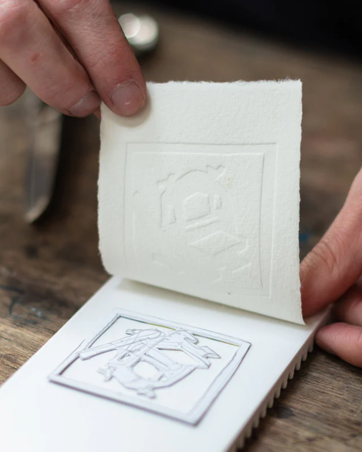

A pneumatic or air press is a mechanical device that physically manipulates a piece of metal using air pressure. It can bend, draw, cut, punch, and quickly create metal components for various commercial applications. For concrete production applications, GEYA provides a free application test for Pneumatic Presses.

Home » Pneumatic Press Manufacturer

We Offer Different Types of Pneumatic Valves

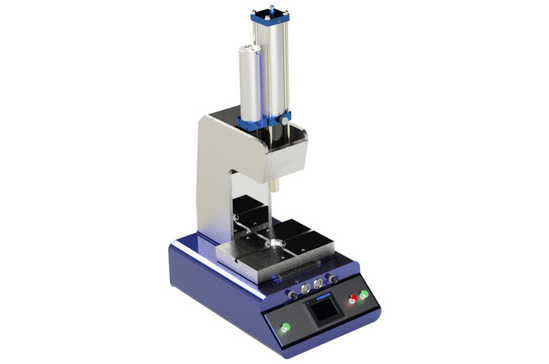

KJ-63 Pneumatic press

KJ-63A Pneumatic press

KJ-80 Pneumatic press

KJ-100 Pneumatic press

KJ-125 Pneumatic press

KJ-160 Pneumatic press

Unleash the power of GEYA’s cutting-edge technology and unrivaled quality. Contact us right now!

Our Pneumatic Press Machine Feature

Our pneumatic press machine has high precision, adjustable pressure settings, quick cycle durations, and design.

- 4-Post Press Construction

- Low Friction Seals in Cylinder

- No hydraulic fluids, reducing spills

Your Best Pneumatic Press Manufacturer

We are always trying to improve the strength and dependability of our presses. We have a wonderful assortment of air presses that are flexible, simple to use, and affordable.

With our years of experience, we will examine your design and construct a bespoke air press that fits your requirements.

Press Machine Applications

Ready to Work Together? Build a project with us!

Frequently Asked Questions

Can a hydraulic cylinder be used as a pneumatic cylinder?

What is air-press technology?

What are the advantages and disadvantages of power press?

- Efficiency and Speed

- Precision and Consistency

- Versatility

- Cost-effectiveness

- Requirement for Skilled Operators

- Potential Safety Hazards

- High Initial Investment