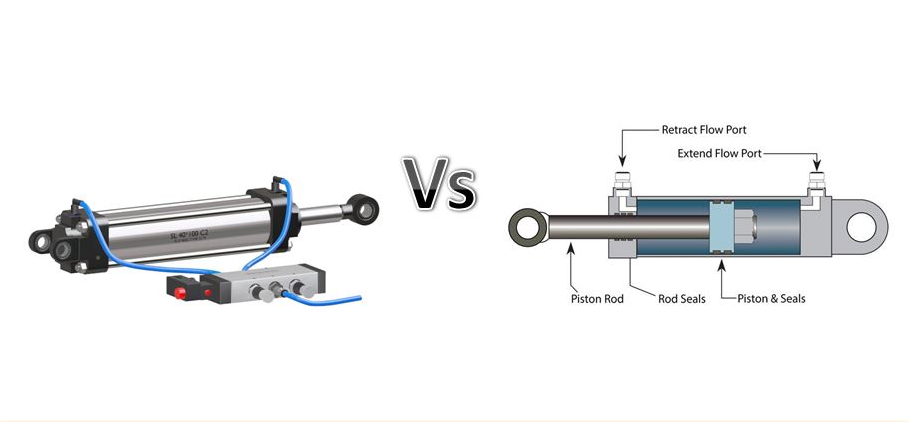

When choosing a particular application, you must determine the difference between hydraulic and pneumatic cylinders. If you are still deciding which of them to select, let us help you go into their details and break down their differences individually to further understand the basic pneumatics and hydraulics.

Hydraulic VS Pneumatic: Pros and Cons

Understanding the advantages and disadvantages of purchasing hydraulics or pneumatics would be best. Aside from having an idea about the specific details, it will also be your ground to security to ensure that you use the suitable device and will utilize its general purpose for your next project.

In this part of the blog, we highlighted some of the pros and cons of the two. Check them out and start your analysis about them.

Hydraulic Pros and Cons:

- A hydraulic can stand greater strength, with more efficiency in operations.

- It has a vital feature of self-lubrication.

- The source of energy and force of the hydraulics has higher durability and quality but is pretty expensive.

- A close and detailed control and quality management of the fluid used in hydraulic type is necessary and required to avoid further complications and leakage.

-

Hydraulic type is prone to fire and potentially dangerous leaks since most fluids are flammable.

Pneumatic Pros and Cons:

- A pneumatic type is powered by a compressible clean air, making it shockproof.

- This requires little effort in close monitoring since it runs a simple and lower pressure.

- Compared to other types, pneumatics is cheaper.

- Since it is powered by compressed air, it requires lubrication occasionally.

- The primary medium of pneumatics is compressible air, making it less powerful.

- It requires proper maintenance due to needing more durable parts.

The Key Differences between Hydraulics and Pneumatics

The presence of hydraulics and pneumatics among heavy-duty vehicles and industrial machines has been in demand, and they are now playing a critical role in most operations connected to the mentioned industries. Each can lift and move heavy objects and stroke lengths using high pressure and weights.

But even with the similarities between hydraulic and pneumatic systems, they are different and unique in some ways. In this part of the blog, we are going to highlight the differences between hydraulic and pneumatic actuators that you need to review to help you decide which of them to purchase for your next application:

1.Medium Used

In terms of the particular medium used to operate, hydraulics uses liquids or fluids, while pneumatics uses compressible air.

2.Maintenance & Management

A pneumatic needs lubrication more since hydraulics already has a self-lubricating feature because it mainly uses fluids to power up.

3,Safety & Cleanliness Measures

Regarding safety, pneumatics are your best buddy because leakage in the air will not cause any corrosion or dangerous consequences. Unlike in hydraulics, dangerous risks could happen when fluid leakage occurs. Additionally, some industries are after cleanliness and not strength, so their best option is the pneumatic cylinders.

4.Strength

Even though pneumatics are more shockproof because of their compressed air medium, most industries rely on hydraulics because they can hold and withstand more strength and weight.

5.Energy Consumption

Since the two cylinders need electrical power to get energized, they have a different level of consumption. Pneumatics uses more energy because the air compressor needs to run continuously. At the same time, hydraulics consumes less because they can recycle the fluids or liquids used through a filtration system.

6.Materials Used

The metals used in manufacturing hydraulics are more durable and of top-notch quality than those used in pneumatics.

7.Speed Motion

In rapidity and high-speed motion, pneumatics have a higher flow rate than hydraulics because compressed air can be released immediately. Additionally, fluids take longer to run due to their level of viscosity.

Conclusion

With the growing demand for massive manufacturing productions, extra challenging work, and heavy-duty operations, the need for hydraulics and pneumatics increased in volume. Hydraulic cylinders are present in operations where strength, force, and power are needed. On the other hand, Pneumatic cylinders are necessary for high-speed motions.

Both hydraulic and pneumatic cylinders play a vital role in different applications and operations of industrial machines, construction equipment, and heavy-duty vehicles. Even with other materials and mediums, they still perform their functionalities very well, depending on where they are utilized. Since the critical differences between the two are already in the highlights of this blog, the details and explanations will help in selecting the right one for your next application or project.