A tandem cylinder is a versatile piece of equipment you can use in most actuator mechanisms, especially those that need more power than a single piston type could provide.And this article will help you know more about it. You’ll learn its meaning, construction, working, types, benefits, and widespread use.

What is a Tandem Cylinder?

A tandem cylinder combines two cylinders in one unit. The cylinders are mounted inline, with each having a piston. A connecting rod typically links the two pistons together and helps transfer their motion to an external mechanism.

With the increased surface area for fluid—air or hydraulic liquid—to act on, this arrangement generates twice the force of a single cylinder of the same bore size without requiring additional pressure.

Depending on the specific use, this device can be a compact unit you insert into an automation system or the robust part of a heavy-duty machine. A good example is the hydraulic system of construction and mining equipment.

Resource: https://www.researchgate.net

Tandem Cylinder Construction

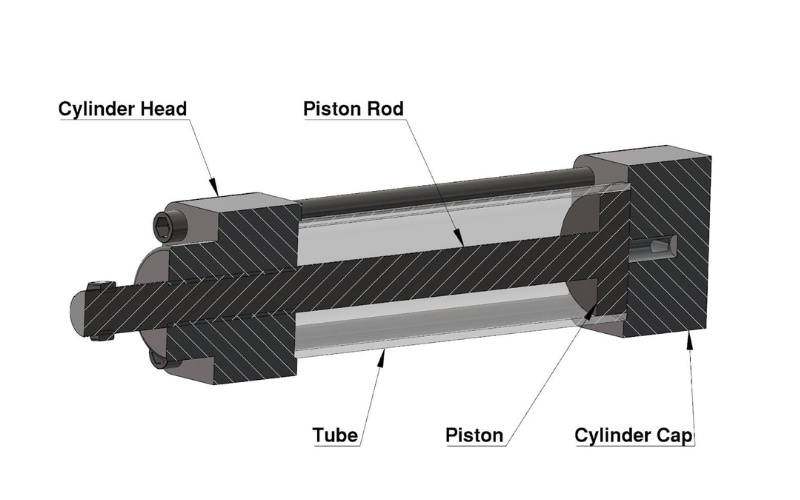

The simple construction of a tandem cylinder comprises these main parts: barrel, piston, piston rod, ports, head, base, ports, and seals. Let’s see what each component does:

- Barrel – this is the housing, the casing that encloses the piston and rod assembly. It’s usually high-grade steel and highly polished on the inside.

- Piston – separates the barrel into sections of low and high-pressure chambers and moves under the action of the fluid pressure. It slides inside the barrel with the help of sliding rings and seals.

- Piston Rod – connects the pistons and moves with them. It transfers motion between the pistons and to the outside (the load). It is usually chrome-plated steel.

- Head – the open end from where the piston rod extends and retracts when pressurized fluid enters the barrel.

- Base – the closed end of the barrel and typically welded to the barrel or attached with screws. In some types of the device, it holds the return spring.

- Ports – these are fluid entry and exit openings. They allow air or hydraulic fluid in and out of the cylinders.

- Seals – help to keep the assembly leak-proof and prevent the pressure loss that leaking fluid could cause.

Resource: https://youtu.be/zmloalFDxU4?si=KJzdZKe7nqfyCNaB

Tandem Cylinder Working

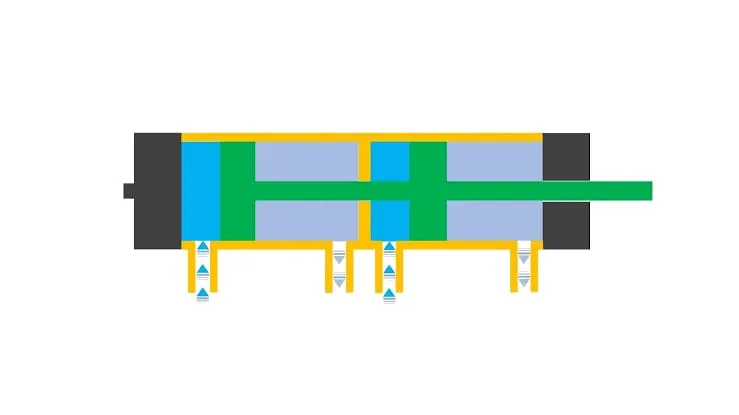

These devices use two stages of fluid compression to multiply force. Fluid under pressure enters through two ports, pushing both pistons. The pistons move and extend a rod. You can then harness the movement to work a load in machinery or an industrial system.

In the reverse stroke, the pistons force the fluid out of the barrel via two outlet ports. The retraction is accomplished by either a return spring or fluid pressure, depending on the construction. This design gives rise to two versions of the device: single-acting and double-acting.

Single Acting

The working stroke (under fluid pressure) only occurs in one direction. The reverse stroke happens with the help of a spring or other external force, such as the load. The single-acting assembly can also be a push or pull type. In the push type, the forward motion is the working stroke and vice versa.

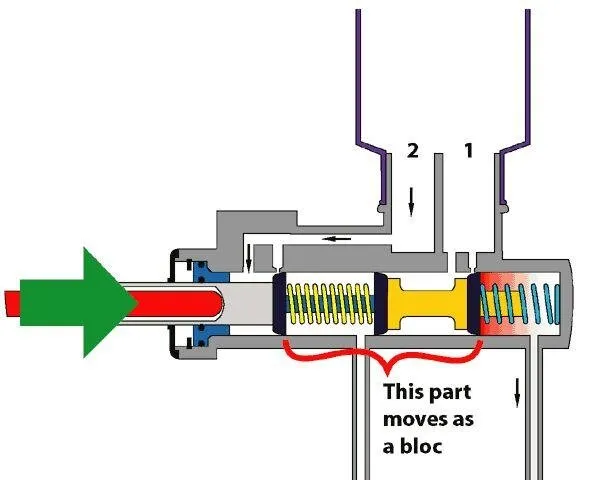

Double Acting

Fluid pressure acts in either direction: forward movement (or rod extension) and backward stroke. In other words, all movements are working strokes. The operation offers a more controlled motion and suits specific systems such as presses and lifting tools.

Resource: https://www.researchgate.net

Types of Tandem Cylinders

A tandem actuator cylinder is a fluid-based device or system. As such, it’s usually either pneumatic or hydraulic type. Each version has its specific benefits—and best uses.

Tandem Pneumatic Cylinder

This cylinder type uses compressed air to work. Two bidirectional cylinders with inlet and outlet ports are arranged inline. During operation, the air enters both chambers simultaneously, pushing the pistons and causing the piston rod to extend, retract, or both.

Being air-powered, it produces less power than its hydraulic counterpart but is cleaner and more economical. It is also faster in operation. As a result, it mainly fits lighter applications that involve smaller loads but require high-speed actuation.

Tandem Hydraulic Cylinder

This version relies on hydraulic fluid, such as oil, to move the pistons. It produces more power than the air-based type and is best suited for heavy-duty systems requiring immense force. Additionally, it offers greater precision and is way quieter.

Despite these advantages, the hydraulic type costs more upfront because it uses robust or heavy-duty parts. It’s also comparatively slower and may not fit high-speed applications like light automation mechanisms.

Resource: https://www.youtube.com/watch?v=G626jno5Iy4

Tandem Cylinder Advantages

This device has several advantages, with its inline arrangement of pressure chambers and pistons. These benefits form the basis of its preferred use in heavy machines and actuator systems. They include the following.

- It doubles the force, allowing you to use a slender device to move large loads, which is an advantage if space is limited.

- Even with the additional cylinder and pistons, the fluid pressure required to operate it remains the same, making it a more economical system.

- With this configuration, you achieve more control and precision, making it helpful where accuracy is an essential consideration.

- You can choose from many options: double or single-acting, pneumatic or hydraulic, and various other design differences.

It’s good to note that the double configuration means an extended length. However, given the multiplied force on the same diameter and fluid PSI, you still get more benefits than those of a single piston.

Resource: https://www.youtube.com/watch?p-ngt8hVTnQ

Tandem Cylinder Application

Tandem or double-piston cylinders are helpful where the force required is higher than conventional single-piston devices can generate or when increased control of the actuation process is necessary.

They produce more power and are available as either pneumatic or hydraulic; it depends on the needed amount of force and other considerations such as noise and precision.

- In manufacturing plants, they help lift, move linearly, and position heavy loads like those in heavy manufacturing industries.

- Robotic systems use them to move various parts like arms, grippers or jaws, and more

- In agricultural machinery, they make parts of plows, crop sprayers, harvesting machines, and other agricultural equipment.

- The construction industry relies on them to operate heavy industrial machinery such as lifting cranes and elevation platforms.

- They find vast use in mining and excavation as hydraulic systems of mobile equipment and tractors.

Conclusion

The tandem cylinder is a fluid-operated device that uses two compression chambers to move larger loads than a single-cylinder configuration. It can also be single-acting or double-acting and pneumatic or hydraulic-based. Depending on your intended use, we recommend understanding how it works before selecting the most suitable type.