Which, between the pneumatic actuator vs. electric actuator type, should you go for? Every year, companies lose thousands of dollars for choosing the wrong actuators for their applications.

It can be a tough decision to make, we know, given the many advantages of each, so we wrote this guide. Use it to understand the difference between the two types of automation devices and avoid setbacks that a wrong choice could cause.

Pneumatic Actuator Meaning

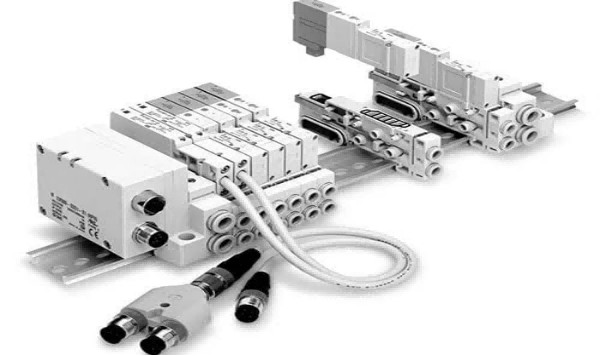

A pneumatic actuator is an actuating device that depends on compressed air pressure to produce motion. The motion operates a load, moving it along a straight line or causing rotation.

Pneumatic actuators have widespread application in the automation world. They are powerful, reliable, and relatively fast. In manufacturing, they make essential parts of process control systems.

Electric Actuator Definition

An electric actuator relies on an electric motor to produce the working force. You can use it with an AC or DC, with the operating voltage typically ranging from 12V to 120V.

Electric actuators are easy to control, precise, and have several other benefits, such as quiet operation and high repeatability. Like the air-based types, they find application in systems where controlled load movement is necessary.

In the next section, we will compare pneumatic vs. electric actuators on several fronts and make selecting the most suitable device for your project easier.

Resource: https://www.designworldonline.com

Pneumatic Actuator vs. Electric Actuator

Both pneumatic and electric actuators produce motion to displace a load. However, they operate using different power sources, cost different amounts, and many other things.

These variations can impact your application in various ways, from productivity to operating expenses. Let’s compare the two devices side by side.

1. Control

Pneumatic actuator control happens via a flow-regulating valve. It can use a pilot signal or a solenoid to control the airflow, increasing its precision and enhancing the level of control.

Electric actuators use an electronic controller to operate the motor and its actuation process. Their control is instant and more precise. You can also vary their actuation mid-cycle, making them best for variable-position applications.

In comparison, the control of an air actuator is less precise, so they suit applications that involve end-to-end positioning. However, these actuators are more responsive than electric types, offering higher duty cycles.

2. Speed

The response time of a pneumatic actuation system is relatively high, taking as little as a second or even less. Electric actuators are slower than air types but faster than hydraulics.

Note that the response speed for each device type varies. Slow and fast pneumatic actuator versions are available, for instance, and the same applies to the other types.

3. Torque

The electric actuator offers higher accuracy levels, given that an electric current is easier to control than airflow pressure. As a result, you can use them in applications that require motion repeatability and multi-point positioning.

Examples of such applications include the valves of large piping systems. Here, the pneumatic actuator systems offer both speed and higher valve turning forces.

3. Accuracy

The electric actuator offers higher accuracy levels, given that an electric current is easier to control than the pressure of air flow. As a result, you can use them in applications that require motion repeatability and multi-point positioning.

Pneumatic types are less accurate and best for two-point applications. That said, applications where accuracy is not a primary concern can significantly benefit from the first response and higher torque of pneumatics.

4. Lifespan

The difference between electric and pneumatic actuator types includes their varying lifespans. The typical air-based actuator can offer over 1,000,000 cycles.

In comparison, most electric-based actuators have a lifespan of 250,000 cycles. That makes the pneumatic type the more durable option.

Again, it’s essential to understand that the life of an actuator, whether air-based or electric, depends on many factors, including usage environments and application types. As a result, it varies widely.

5. Cost

Pneumatic actuators are generally cheaper upfront than electric types. Depending on several factors, such as size, the pneumatic actuator price can start from as low as $15.

However, the costs to run a pneumatic system can be high since you need electricity to compress the air. Air actuators also require hoses and other parts to supply and vent the air.

In terms of maintenance, the pneumatic actuator uses a simple design with fewer parts. That makes them cheaper to maintain. Compared to electric actuators, air-based actuators also last longer.

Resource: https://www.designworldonline.com

Pneumatic Actuator vs. Electric Actuator in Application

Applications vary greatly. Therefore, your type of project should determine the type of actuator to use. Before choosing, evaluate each actuator type carefully and consider the cost to acquire and use. Here’s our advice:

When to Use Pneumatic Actuators

- If your application involves working with flammable materials and you do not want a device that will not produce sparks

- In high-heat conditions, the pneumatic type is your best option. It can generally operate in temperatures up to 250 degrees Fahrenheit

- Use pneumatic actuators if space is a concern. They are generally more compact than similar electric versions

- If fast operation is a primary requirement. Pneumatically-controlled actuators react more quickly

- If higher actuation forces are required. Pneumatics are more powerful.

When to Use Electric Actuators

- If compressed air is not readily available due to cost and other constraints

- For noise-free environments. They are generally quieter

- If higher accuracy levels are needed or multi-point positioning.

Conclusion

When comparing pneumatic vs. electric actuators, a lot goes into choosing the right type of actuator to use. Each device type has its pros and cons. As this article has outlined, pneumatic valves are more compact, fast-acting, and relatively cheaper. Electric types are efficient, accurate, and quiet. Your application should, therefore, form the basis of your selection.