A pneumatic valve actuator utilizes air under pressure to automate valve control. At the heart of any actuator is a movable component. The air pushes the part up and down, back and forth, or turns it on a shaft to position a valve element.

Read this post to understand how pneumatic valve actuators work based on the specific design and motion type.

How Does a Pneumatic Valve Actuator Work?

A pneumatic valve actuator turns the force of compressed air into the mechanical energy of motion. It then uses this motion to position a valve and can either throttle or put it on an on/off mode.

Some actuators move along a straight line, while others cause rotation. Depending on the design, some may use a spring to retract at the end of a stroke. Others rely on air pressure for both forward movement and retraction.

You can also explain pneumatic valve actuator operation by its starting position. In that regard, we have the air-to-open and air-to-close actuators. The following section has the working of these devices explained:

- Linear motion and rotary motion pneumatic valve actuators

- Single-acting and double-acting pneumatic valve actuators

- Air-to-open and air-to-close pneumatic valve actuators, also called fail-open and fail-closed actuators

Resource: https://www.youtube.com/watch?v=BqFJVqr09Ik

Linear and Rotary Pneumatic Valve Actuator

A linear actuator produces motion in a straight line. In other words, it directly moves the stem in and out of the valve. On the other hand, a rotary type generates rotational motion either directly or with the help of a motion-converting mechanism. Let’s see how each works:

Pneumatic Linear Valve Actuator

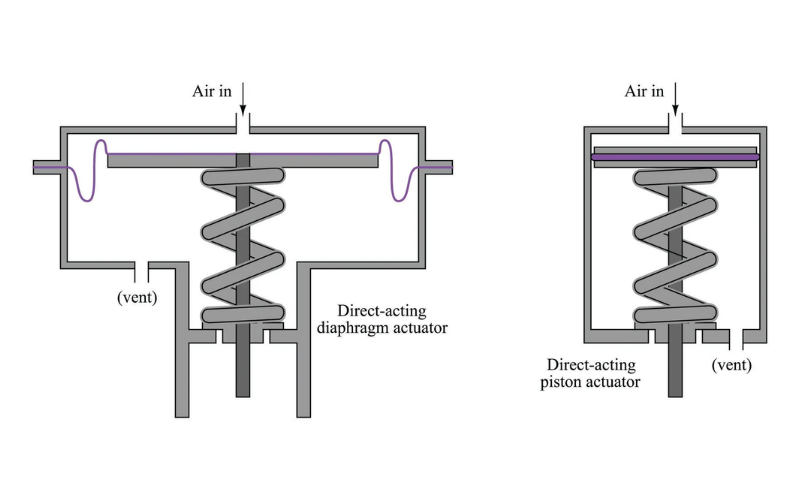

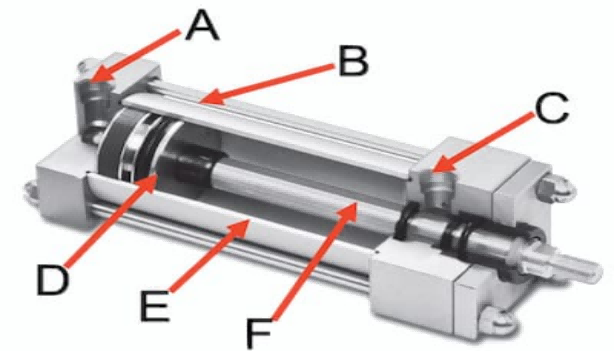

Compressed air acts against a surface in these mechanisms, pushing it up or down. The resulting displacement moves the valve stem. As the stem moves in and out of the valve body, it positions the on/off element to control flow.

At the end of a stroke, a linear motion actuator may use a spring to retract. It may also work without a return spring and rely on air pressure to move forward and back. Sometimes, these actuators use both spring and air pressure.

Examples of linear pneumatic actuators are the piston and diaphragm types. These use a movable component that divides a pressure-tight housing into two, allowing the control of compressed air to produce motion.

Pneumatic Rotary valve Actuator

Rotary actuators convert the linear movement of a piston or a rotating vane. They are either purely rotary or, directly turning the valve, or linear-to-rotary motion types.

A vane mechanism, for example, is a rotary-rotary. A rack-pinion or scotch yoke type of actuating device must generate linear movement before changing it into rotation. You can call them linear-to-rotary pneumatic valve actuators.

Depending on the type of valve type, an air-operated rotary valve actuator can turn various degrees. These range from quarter turns or 90° to complete 360° revolutions.

Resource: https://www.researchgate.net

Single Acting and Double Acting

In a single-acting valve actuator, air pressure only acts on one surface of the moving component (piston, vane, or diaphragm). A spring helps return the actuator to its original position. A double-acting mechanism applies pressure on either side. Here’s how each works:

Single Acting

A double-acting actuator receives air on one side of the housing to compress or extend a return spring while providing the actuating force to position the valve.

At the stroke’s end, the spring’s energy helps pull the moving component back. Air and spring action may help operate the valve in some spring-loaded mechanisms.

Double Acting

A double-acting pneumatic valve actuator does not require a spring. Instead, compressed air acts on both sides of the moving component at the start of a stroke and after.

For the actuator to allow air pressure on both sides of the air-tight chamber, it has air supply ports on either half of the sealed enclosure. At the end of travel, air exhausts through the supply port on the other side.

Resource: https://www.youtube.com/watch?UZYNxJic58

Air to Open and Air to Close Pneumatic Valve Actuator

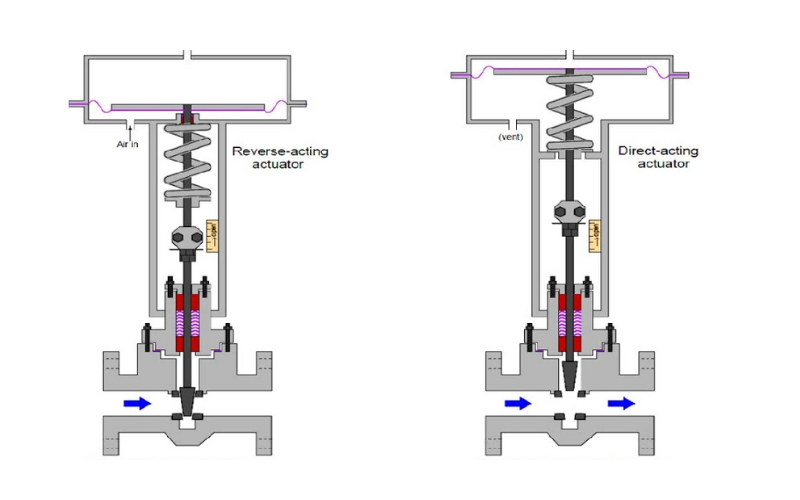

An actuator works based on its starting position and can be an air-to-open or air-to-close mechanism. The air air-to-open type requires air pressure to open a valve. On the other hand, an air-to-close actuator uses air pressure to close the valve; more about that below.

Air to Open Pneumatic Valve Actuator

In an air-to-open pneumatic valve actuator, introducing compressed air into the chamber causes a normally closed valve to open. An air-operated device of this type is also called a fail-close actuator.

In its inactive mode, the valve remains in the closed position. This type of device is in the above image, with its parts and those of the valve labeled.

Air to Close Pneumatic Valve Actuator

The air-to-close valve actuator uses air to close the valve. You use it to position “normally-open” (NO) valve types. It keeps the valve remains open when not activated.

You can also call it a fail-open valve actuating device since it fails in the valve-open mode when air pressure reduces. Under the action of compressed air, it moves the stem to position the valve element.

These actuating mechanisms suit applications where a closed valve is safer than an open one. In the above images, you can see an example of an air-to-close pneumatic actuator for valves.

Conclusion

In this article, we looked at the working principle of different versions of the pneumatic valve actuators. The information should be helpful when finding the correct actuator for your project. That’s because each mechanism type has ups and downs, and the right option depends on the valve type and required operation benefits.