The pneumatic vacuum is an automation device for many industrial and non-industrial systems. It uses airflow to create a vacuum and perform various tasks such as pick-and-place, cleaning, evacuation, drying, and even filtration.

This article takes you through the pneumatic vacuum-generator working principle, detailing everything you need to know about its operation and components.

Working Principle of Pneumatic Vacuum

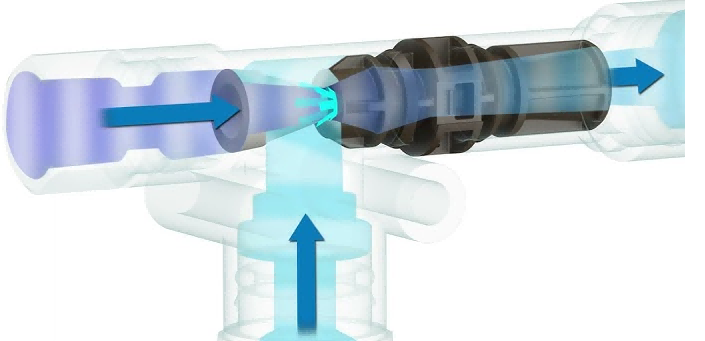

A pneumatic vacuum accelerates compressed air (or other fluid type) through a constriction to create a low-pressure condition. It then uses the resulting vacuum to generate suction and lift or grip things, among other functions.

A typical air-operated vacuum device relies on the Venturi effect and Bernoulli principle to turn positive fluid pressure into negative pressure (an increase in fluid velocity causes pressure reduction and vice versa).

Using the Venturi principle, a Venturi vacuum generator takes in air and creates suction before exhausting the air through a secondary chamber and port. Using the Bernoulli principle, the device can work on porous pieces with discharge ports in the suction caps.

Resource: https://www.youtube.com/watch?v=1p2zIOdz0Mw

Vacuum Generator Principles of Operation

At the heart of a typical pneumatic air vacuum is a nozzle with a constriction, a low-pressure part called a diffuser, a vacuum port, and the exhaust. Let’s see how it works:

- During operation, the device takes in compressed air through the nozzle

- The air then passes through a narrower part of the nozzle

- This causes the air to move at a lower speed and high pressure (Bernoulli principle)

- The air expands in the diffuser, the broader part of the air path, and its velocity increases

- This results in a drastic reduction of pressure (near vacuum), creating a Venturi effect

- Air from outside rushes in to fill the gap, generating suction at the vacuum port.

- A valve is usually included in the system to control airflow and create or stop a vacuum

By placing suction cups or other component at the vacuum inlet, the vacuum air vacuum can grip or lift things and perform other tasks such as evacuation, or drying and filtration.

Parts of a Pneumatic Vacuum System

A complete pneumatic vacuum system comprises an air compressor, the vacuum generator itself, and the various fittings the system requires to work. Let’s see the function of each of these parts.

Air Compressor

The vacuum system uses a compressor to supply air under pressure. The compressor has a reservoir that stores air under pressure for use by the generator. It sends the pressurized air to the generator whenever needed and usually includes flow control valves and other fittings.

Venturi Vacuum Generator

From the compressor, air enters the vacuum-generating part of the system. The vacuum generator, on the other hand, contains the nozzle, a suction port, and a discharge or exhaust opening.

- The nozzle directs airflow to generate a vacuum. It narrows down to increase the fluid pressure and reduce flow velocity before widening into a diffuser to expand the air and reduce pressure levels.

- The suction port utilizes the generated vacuum to create suction and perform the required tasks such as lifting, gripping, evacuation, etc.

- The discharge helps remove air after achieving the required action.

Pneumatic Vacuum Hoses and Fittings

These are components that the air vacuum system needs to operate as it should. They include valves, an air filter, hoses, and several other parts.

- The valve or valves regulates the gas flow in the system to start or stop vacuum generation.

- The pneumatic vacuum filter is the component that removes particulates from the gas.

- Hoses help convey gas from one part of the system to another and are vital components of any air vacuum system.

- A silencer is usually included at the discharge to reduce the noise that exiting air might produce.

- A pneumatic vacuum lifter uses suction cups. These attach to work pieces and create the lifting power.

Resource: https://www.packworld.com

Single-Stage vs. Multi-Stage Pneumatic Vacuum

A compressed air vacuum Venturi system is either a single-stage or multi-stage type. These have design differences but also differ in the amount of vacuum force they can generate, among other variations.

Single-Stage Vacuum Generator

A single-stage system only uses one nozzle. It’s a simple design that generates less force than a multi-stage vacuum system and typically suits lower suction force systems. These include the pick-and-place systems in the electronics industry.

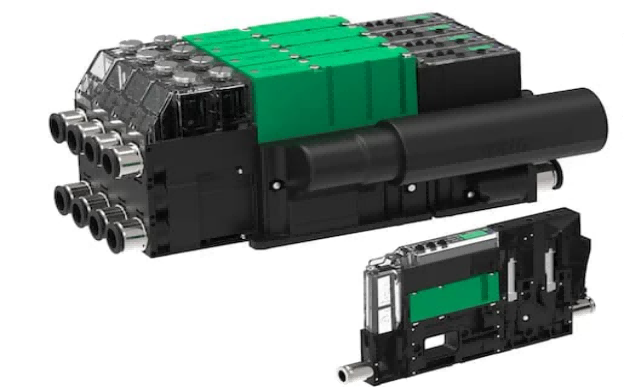

Multi-Stage Vacuum Generator

A multi-stage vacuum generator has more than one nozzle. Using multiple nozzles increases the suction pressure without necessarily requiring more air. As a result, it’s a more efficient option in the world of pneumatic or air-operated vacuums and is suited for use with higher loads.

Vacuum Generator vs. Vacuum Pump

“Pneumatic vacuum” and “vacuum pump” are often (and wrongly) used interchangeably. While both generate a “vacuum,” the machines differ in several ways. Here’s how including their best applications.

- A vacuum generator pump uses electricity to produce a low-pressure zone, and is often equipped with an impeller motor. Pneumatic vacuums rely on compressed air to work.

- A vacuum pump has moving parts; a compressed air vacuum generator does not.

- Electric vacuum pumps generally produce higher suction forces and best suit uses that require such.

- Vacuum pumps are generally larger than air-operated vacuum generators.

- Pneumatic vacuums are comparatively quieter than electric vacuum pumps.

Resource: https://www.youtube.com/watch?v=XCwfeAWe1Ys

Pneumatic Vacuum Applications

You can use a pneumatic or air-operated vacuum generator to accomplish various functions. The following are its most popular applications.

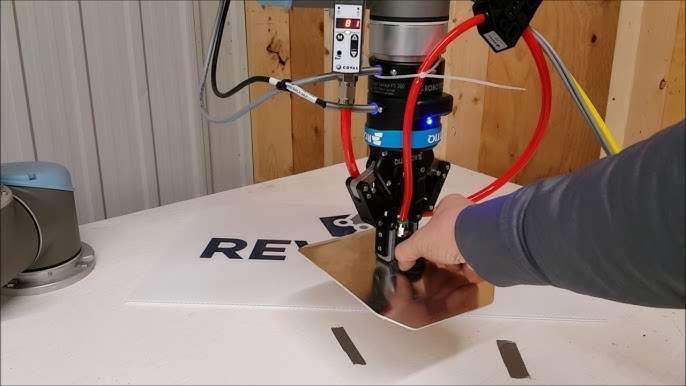

- In industrial systems, vacuum generators are the heart of pick-and-place machines or robotic gripping arms

- In science labs and other sectors, the device helps evacuate, dry, clean, or perform other functions such as filtration

Integrating a pneumatic or Venturi vacuum generator in an automation system offers several benefits, making the device the most used in industrial settings.

- The device is light and compact, and you can easily integrate it into a system for automation.

- Pneumatic or compressed air vacuums have no moving parts and are almost maintenance-free systems with minimal wear.

- They do not require electricity to run, do not generate heat, and are safer in explosive environments.

- Compressed air-generated vacuums are fast-acting and suited for high-speed, rapid-cycle applications.

Conclusion

The pneumatic vacuum is helpful in many industrial systems, from packaging to material handling. Compact and lightweight, it offers easy integration into automation systems. These devices also contain no moving parts and are virtually maintenance-free, among other advantages such as fast action and safety around flammable materials.