Pneumatic actuators play a crucial role in valve automation, enabling the remote operation of pipelines and other flow systems. Today, you can choose from a range of pneumatic actuator types. These are available in various mechanisms and working options. Before delving into the actuator types, here’s what they are.

What is a Pneumatic Valve Actuator?

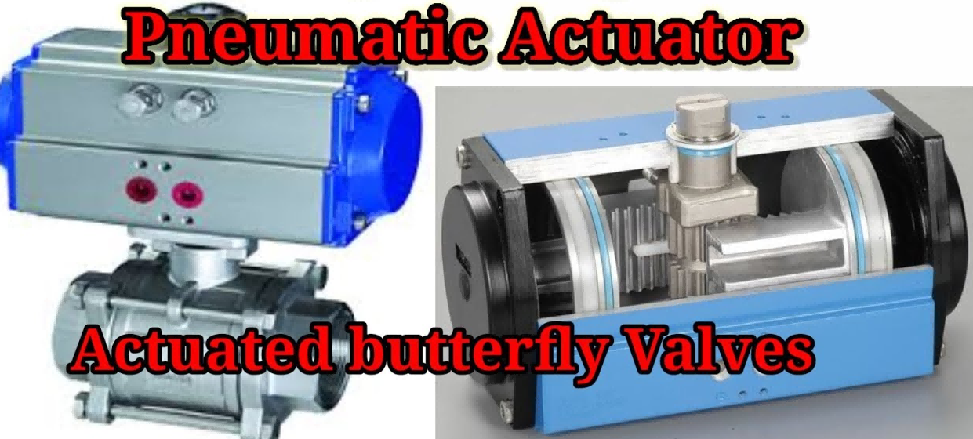

A pneumatic valve actuator is a mechanism that uses compressed gas to operate a valve. It turns the force of compressed air into linear or rotating motion, enabling the automated positioning of valves.

Valves control the flow of materials in pipelines and process systems. When paired with actuators, it becomes possible to operate them remotely and from a central location.

You can use an air-operated valve actuator in a range of applications. For example, it can be a pneumatic actuator for a ball valve in an industrial process or a wastewater gate valve with a pneumatic actuator attached.

https://www.youtube.com/watch?v=tAdSsbB9arA

Pneumatic Valve Actuator Types

Pneumatic valve actuator manufacturers produce various versions of this device. These cater to the different application types based on the required torque and other needs. The types of actuators are by their operating mechanisms and include the following:

- Diaphragm type

- Cylinder based

- Rack and pinion gear actuator

- Vane type

- Scotch yoke valve actuator

1. Diaphragm Pneumatic Valve Actuator

These actuators produce motion along a straight line. They typically use a flexible membrane inside a fully-sealed housing. The diaphragm attaches to the valve stem in the middle. On the edges, it rests between the housing rims, dividing it into two halves.

A metal plate is usually placed in the middle of either side to reinforce the diaphragm. On the other hand, the sealed chamber has two different ports: air supply and exhaust ports.

The diaphragm pneumatic valve actuator may also be single or double-acting. In the single-acting type, a spring helps push the diaphragm back. In the double-acting actuator, air pressure acts on both sides of the diaphragm.

Working:

- The controller instructs the actuator to close the valve

- Air flows into the upper chamber and pushes the diaphragm

- The diaphragm moves down, compressing the spring and pushing down the stem

- The valve closes

- When pressure reduces, the spring pushes the diaphragm to its former position

- The stem retracts, causing the valve to open

- A positioned within the regulates the air amount, while a position indicator helps show if the valve is open or closed

- In some diaphragm actuators, the air supply port is on the lower side of the chamber.

- In this design, the diaphragm moves up to open the valve and down to close it.

Application

Diaphragm actuators are best with flow control valves like the globe type. Applications range from the food industry to pharmaceuticals and industrial flow lines like wastewater and chemical pipelines.

2. Piston Pneumatic Valve Actuator

The piston pneumatic valve actuator uses a piston and rod assembly moving inside a cylindrical chamber to operate a valve. The piston provides the surface area for air to act on.

On the other hand, the rod that connects it links with the valve control component, allowing the actuator to open and close or throttle the valve.

Like other pneumatic valve actuator types, the mechanism is single-or double-acting. The single-acting type relies on the energy of a return spring to retract. In the double-acting actuator, air can act on both sides of the piston

Working

- Compressed gas enters the actuator cylinder through the air supply port

- Its force acts on the piston, pushing down and compressing the spring

- The stem moves downward, closing the valve

- Air pressure reduces, and the spring pushes the piston up

- The valve opens.

Application

These actuators can be powerful. They suit applications where the valve requires much force to open and close. Their linear motion also makes the best for valves with stems that must travel long distances.

3. Rack and Pinion Pneumatic Valve Actuator

The rack and pinion pneumatic valve actuator produces rotary motion using rack and pinion gears. The rack gear is a straight gear with a toothed surface. It typically mates with a pinion gear (round gear) to convert linear motion to a rotation.

The two gears connect to a piston and rod assembly inside a sealed chamber in the rack and pinion actuator. The housing has a port to supply air on one or both sides and an exhaust vent to remove it.

Working

- During operation, air pressure pushes against the piston surface

- This moves the rod

- The rod, in turn, moves the rack gear

- The rack gear rotates a pinion, turning the straight-line motion into a rotation

- The pinion transfers the motion to a drive shaft to operate the valve

- Again, the rack and pinion actuator can use a spring or air pressure to retract.

Application

Rack and pinion mechanisms are common in automation systems, including mixing, feeding, positioning, and lifting. They operate quarter-turn valves and are typically best for lighter applications.

Vane Type Pneumatic Actuators

Resource: https://valve-world.net

Vane-type pneumatic actuators typically consist of a vane connected to a drive shaft and enclosed in a pressure-proof chamber. These offer the advantage of compact design with higher turning forces. Being a purely rotary actuating device, it has no motion transfer losses.

The vane provides the surface for the compressed gas to act on and transfers the resulting motion to the valve mechanism. It swings in either direction, depending on the surface the air pushes against.

Working

- A supply opening introduces pressurized air into the chamber

- Its force pushes the vane

- The vane swings inside the sealed chamber

- Its motion rotates the valve stem to open or close the valve

- To retract, the vane-type actuator may connect to a return spring or rely on the action of compressed gas on the opposite side.

- Spring-based actuators are called single-acting types, while those that use gas pressure are double-acting.

Application

Use vane-type pneumatic actuators with rotary valves such as butterfly or ball valves. These devices also fit applications when the space to install an actuator is limited. They are compact and use a simple working mechanism.

5. Scotch Yoke Pneumatic Valve Actuators

These pneumatic valve actuators use a scotch yoke connected to a slider and a piton-rod assembly. It converts the linear motion of an air-operated piston into rotary motion.

A slider connected to a slot in the yoke moves back and forth under the action of the piston. A return spring compresses at the start of the actuator operation and extends at the end of the stroke.

Working

- Air under pressure enters the actuator housing

- The compressed air pushes the piston

- The piston moves a rod

- The rod moves a slider and rotates the yoke

- The valve opens

- Air pressure reduces

- The spring extends and moves the slider

- The yoke rotates and opens the valve

Application

Given their high torque, Scotch yoke actuators suit the large quarter-turn valves of oil and gas industries, power plant installations, and other piping networks. You can use them to modulate flow or as valve on/off devices.

Conclusion

Today, you can choose from a broad range of pneumatic valve actuator types, from diaphragm or piston and cylinder to vane-based and those that use rack gears or scotch yokes. Depending on the application type, you may choose between a rotary and linear actuator. We recommend understanding how each type works before selecting the best mechanism for your needs.