Introduction To Pneumatic Manifolds

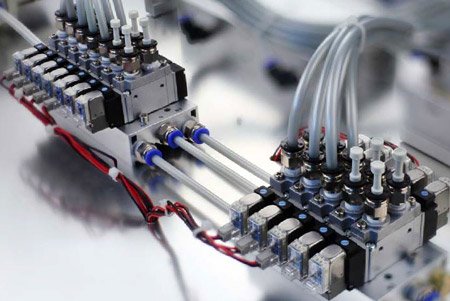

Do you work with manifolds every day? Is this your first time working with manifolds? What is a pneumatic manifold? It’s a device responsible for dispensing liquid or air from a singular source to multiple outputs. If you look at it a little closer, a pneumatic manifold is a junction for different outlets in any distribution system.

They are also referred to as pneumatic distribution manifolds. Different manifold manufacturers provide different configurations. Therefore, when looking for a new pneumatic manifold, take the time to assess your needs. On the other hand, they are available in different materials, especially aluminum and nylon.

Importance of Pneumatic Manifolds

In any distribution pneumatic system, the importance of having a manifold can’t be understated. As stated above, they connect different paths to create a singular structure. They are hugely responsible for simplifying the process of air distribution.

On the other hand, they make the entire system more compact and properly organized. Manifolds also assist in pressure regulation, timing, and the overall air direction inside the system.

One of the best ways to improve the efficiency of your distribution system is by introducing pneumatic manifolds. You can save a lot of space since they channel anything from one singular source to multiple sources. You can use the extra space to install extra equipment or components as you may wish.

How Does A Pneumatic Manifold Work

Simply put, a compressed air manifold works as a control center. Here, it distributes and directs the flow of air or liquid to various components in the system that utilize compressed air. It is connected to multiple outlets from one or more sources to improve overall distribution.

When looking for pneumatic manifolds for your system, it’s important to consider various configurations. These include flow rates, housing materials, port sizes, pressure rations and station counts. You can mix and match from different manufacturers to get the best fit for your needs.

Depending on your system needs, you must identify the best pneumatic manifolds for the best results. Therefore, you need to research the materials, brands and system recommendations to avoid damage or system failure in the long run.

Types of Pneumatic Manifolds

Parallel Manifolds

If you want to optimize and simplify your pneumatic system, you can’t go wrong with parallel pneumadyne manifolds. You can enjoy an easy and quick connection with different devices.

Even better, there is one-touch installation and easy removal options. You can also connect different tubes, especially if they are made from different materials effortlessly.

One of the disadvantages of parallel pneumatic distribution manifolds is that they take up too much space. You will likely end up with multiple connections that could have been prevented. As such, they are useful for small-scale productions.

Series Manifolds

If you want to connect and disconnect tubes effortlessly, series pneumatic manifolds with valves are a great choice. Setup and maintenance of this type of manifold is also effortless. It is a great advantage for large-scale distribution because it allows numerous connections from a singular source.

As the name suggests, they can help connect a series of inlets and outlets effortlessly. They are a space saver for your pneumatic system and come in a flexible design for the best results. They are also cost-saving, especially if you are running a large-scale distribution system.

Components Of Pneumatic Manifolds

Ports And Connections

Ports and connections found in pneumatic manifolds are responsible for connecting multiple tubes to one fitting. Note that most pneumatic systems require the installation of multiple components in a compact manner.

Ports and connections are available in different sizes depending on the pneumatic application. Manifolds are manufactured with exhaust and inlet ports on each end to ensure effortless distribution.

Valves Blocks And Subplates

Pneumatic valve manifold blocks are placed at each end of the port. They are responsible for critical roles such as blocking connections to the process and regulating the pressure found between any two ports. If you take the time to install valve blocks properly, you will enjoy a seamless distribution system.

Subplates are also components you will find on your pneumatic folds. Depending on how your system is designed, subplates will make it easier for different port styles and locations to match accordingly.

Pressure Regulators And Gauges

Any excess pressure in your system is dangerous. Therefore, you need pressure regulators to maintain stability. If there is any pressure change (small or negligible), take quick action to stabilize it immediately. You need to perform routine maintenance on your pressure regulators and gauges to ensure they work properly.

Benefits Of Pneumatic Manifolds

Enhanced Efficiency

Pneumatic manifolds play a huge role in enhancing efficiency in any system. Since they allow multiple connections, they reduce system complexity and ease of use. With the installation of pneumatic manifolds in your system, you will notice fewer interruptions with downstream production.

Additionally, they allow you to use all the resources in your system, reducing wastage. Also, your system will match the required output effortlessly.

Space Savings

If you don’t utilize pneumatic manifolds in your system, singular connections will take up too much space. As such, you may require a larger surface area than necessary to install a single distribution system.

Fortunately, pneumatic manifolds can operate with more than one connection in a smaller space. Therefore, you will improve space savings and utilize the additional space for anything else.

Maintenance And Troubleshooting

Pneumatic manifolds are often exposed to high levels of heat and pressure. They are likely to break down regularly. Therefore, you need to diagnose the problem early enough to fix them properly.

However, maintenance and troubleshooting for pneumatic manifolds is effortless. Since it’s a single manifold connected to various outlets, it’s easy to diagnose and fix the problem.

Installation And Maintenance Of Pneumatic Manifolds

Proper Installation

The installation process of pneumatic folds is straightforward. However, you need to confirm the following aspects.

- The mounting patterns in pneumatic manifolds are brand-specific. Therefore, you must check the mounting patterns before buying and installing the pneumatic manifolds.

- The pressure requirements of your system will also help you understand the type of manifolds to install. With the wrong manifold, you may experience too little pressure on the final valve if the first ones are open.

When installing pneumatic manifolds, you must thread the pneumatic fittings into the ports on the distribution block. This will produce a very organized and compact distribution method. It’s easy to supply more than one line from one source.

Routine Maintenance

Routine maintenance of pneumatic manifolds is the best way to ensure the entire system runs properly. Here are some of the best maintenance tips to ensure proper functioning.

- Every 8 hours, you need to lubricate the manifold. You can use a light-grade oil or a properly graded silicone.

- Next, you need to torque the manifold and then use your hand to rotate it slowly after turning on the air supply.

- Also, you need to perform routine maintenance of the position of the pneumatic manifold. It is set using a pin mechanism and should always be maintained to avoid operational challenges. Changing the pin position may cause delayed or premature filling nozzle action, causing erratic fills.

- Maintenance of operating air pressure is critical to prevent equipment failure. The right air pressure depends on the system requirements and manufacturer recommendations.

- Use breakaway fasteners to protect the pneumatic manifold. Keep some spares around for any quick replacements whenever necessary.

- Make sure there are spare manifolds in place for quick replacements. They will come in handy in the event of failure or damage.

Troubleshooting Common Issues

- Actuators moving too slowly will result in excessive air choke. This may be caused by incorrect flow control adjustment and can be corrected by readjusting the valve. Do you have a plugged air silencer? Take the time to clean it properly or replace it where necessary.

- Have you noticed low pressure on your system? Check the regulator valves for any damage or incorrect adjustment, then replace or readjust accordingly. If you notice some system leaks, you need to fix them immediately.

- Have you noticed that the coil is not picking up? This may be caused by the directional valve’s failure to change position due to electric failure. Start by checking the electric failure and fixing the movement of the mechanical spool.

Conclusion

You need to learn a lot about pneumatic manifolds, especially if you have an air or liquid distribution system. Besides learning about the different components, take the time to learn the proper maintenance procedures to avoid frequent breakdowns and ensure durability. If there is any doubt about your system type, you can always rely on the manufacturer’s recommendations to solve the problems.

If you are troubleshooting the common problems with the manufacturer’s manual, always be on the lookout for the pneumatic manifold symbol for further guidance. Pneumatic manifolds play a huge role in any system. Without proper installation or routine maintenance, you may end up with a malfunctioning distribution system.