Single Acting Actuators

What is a Single Acting Actuator?

Valves and actuators play a massive role in large and small-scale industrial applications. Before installation of pneumatic actuators, you must know your system requirements. Pneumatic actuators are categorized into either single-acting or double-acting.

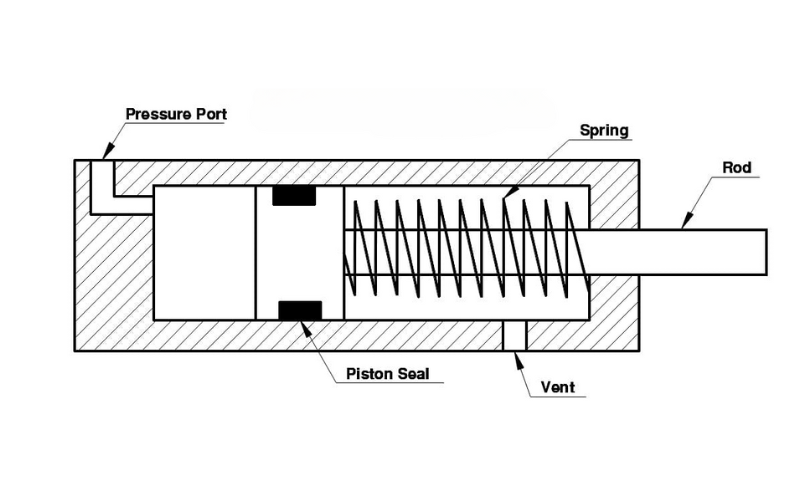

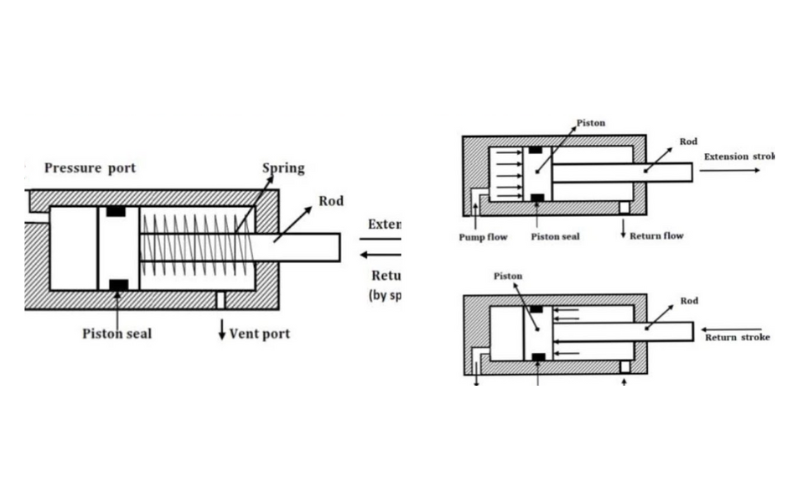

A single-acting actuator is also referred to as a spring-return actuator. When opening a valve, a single-acting actuator relies on air. However, when closing the valve, it uses a mechanical spring.

How Single Acting Actuators Work?

Compressed air is supplied to one side and is responsible for moving the piston in one direction. On the other hand, when closing the valve, the mechanical spring comes in handy. Note that single acting actuators preserve compressed air but can only perform in one direction.

However, the mechanical spring brings the actuator in a defined position. It is considered a safe positioning for the valve. However, it may cause some disadvantages, primarily because of the inconsistent force in the output.

You can’t go wrong with single-acting actuators if you run an application with low to moderate cycles. In most of these applications, a valve failing at the wrong time may result in a safety hazard or severe damage to your equipment.

These actuators will always act as a fail-safe and ensure the valves return to their normal position. For a reliable and safe system, single actuators are an excellent choice for your applications.

Advantages and Limitations of Single Acting Actuators

Some of the advantages of single-acting actuators include the following.

- If you want something affordable that can work with an application with only one direction movement, you can’t go wrong with single acting actuators. They have a very straightforward design that contributes to easy maintenance and installation.

- You will use less air pressure for your application when using single acting actuators. Single acting pneumatic actuators rely on one signal. Therefore, there is considerably lower air consumption, resulting in energy efficiency in the long run.

- If there is a sudden loss in air pressure which a malfunction in your application may cause, the single acting actuator springs into action as a fail-safe, thereby returning the application to its original position.

However, there are some disadvantages to using single acting actuators, such as the following.

- Some single acting actuators may work similarly to double acting actuators, but they don’t offer the same level of control. Since they rely on a single pneumatic signal, they don’t achieve the same precision levels as their counterparts.

- The mechanical spring found in a single acting actuator is very likely to be damaged or fail resulting in unexpected loss in your application.

- Single acting actuators are not mainly used for complex applications. They can’t keep up with these complex and intricate industrial setups.

Double Acting Actuators

Understanding Double Acting Actuators

Double acting pneumatic actuators are commonly used in many applications. They rely on air pressure for opening and closing valves compared to single-acting actuators. The mechanical spring in a single acting actuator is the least durable component.

However, a double-acting actuator’s lack of a mechanical spring makes it more durable. Therefore, they are mainly used for high-cycle applications.

Double Acting Actuator Working Principle

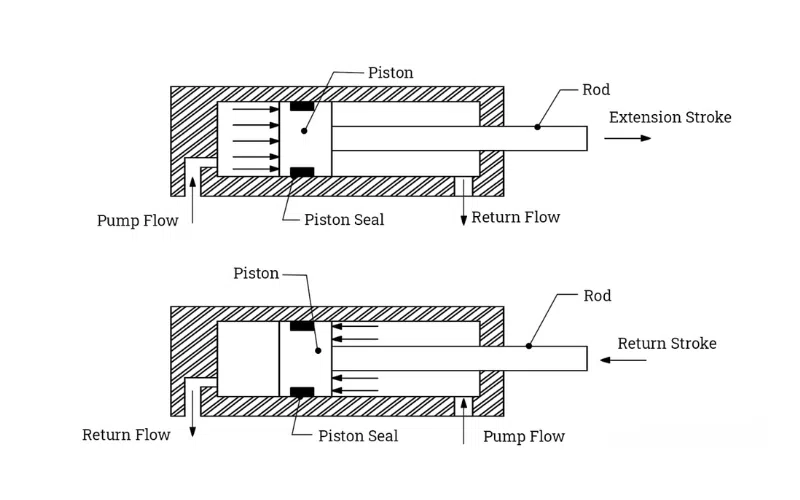

Compressed air is supplied to both sides of the valve, with a double acting actuator. The piston moves to the other side effortlessly if the air pressure is higher on the opening side. Double acting actuators are mainly used if work needs to be done on both sides.

One of the most notable advantages is a constant force in the output from start to finish. They are perfect for applications with higher cycles. Double acting actuators are applicable if there is no significant damage to your application if the valve fails to the closed or open position after a power outage.

They are popular choices for most applications since they are durable and reliable. If you don’t have enough space in your installation and are looking for something compact, you must choose double acting actuators. With these choices, you will have extra room to add new components or equipment to your application.

Pros and Cons of Double Acting Actuators

Some pros of using double acting actuators in your application include the following.

- Double acting actuators provide precise and controlled motion for both directions. Since they have dual pneumatic signals, they can achieve the best precision during positioning. As such, they are the best choice for applications requiring high-level accuracy.

- Double-acting actuators are mostly used in high-cycle applications due to their reliability. They come in handy for most of the complex and intricate industrial applications.

- Since they don’t have a spring mechanism for the return process, there is no likelihood of sudden damage or failure.

- Since double acting actuators control both positive and negative signals, they have a faster response time. As such, they are perfect for time-sensitive applications.

Some disadvantages of double acting actuators include the following.

- The double acting pneumatic cylinder principle relies on more compressed air to function correctly. In the long run, this may harm the overall energy efficiency and increase your operating costs with time.

- They are costly compared to single acting actuators because of the difference in working principles. Double acting pneumatic valves are more sophisticated and complex, especially with installation and maintenance.

- In some situations, double acting actuators have some potential reliability concerns. Yes, they are generally reliable but will likely encounter challenges due to the intricate designs.

Key Differences Between Single Acting and Double Acting Actuators

Force Generation and Direction

Single acting actuators generate motion in only one direction only. As such, they rely on a single source of energy and a mechanical spring for the return stroke. On the other hand, double acting actuators generate motion in both directions by relying on two chambers or ports for bidirectional force.

Simply put, if you have an application that requires a single direction, single acting actuators are a great choice. However, double acting actuators must be installed for those with bidirectional force and movement.

Speed and Precision

Do you have an application without 100% accuracy in positioning? Single acting actuators are a good choice. On the other hand, double acting actuators are primarily used for applications that require 100% accuracy.

On the other hand, single acting actuators are primarily used in less complex systems since they require less speed and precision. Double acting actuators are the best choices for intricate applications with many interdependencies. They are adaptable and always offer seamless integration for your application.

Applications and Use Cases

Single acting actuators are the best choice if you operate on a modest budget with lower upfront costs. On the other hand, double acting actuators can be used for applications that require a higher upfront cost. However, with improved efficiency and 100% accuracy, the cost will be justified in the long run.

Single acting actuators are primarily used in industrial applications where the force is used in one direction. Some applications for single acting actuators include:

- In clamping applications, you need to hold a component or part of the equipment in place. This is useful in the woodworking industry, where these actuators can hold wood pieces in place as they are drilled or cut.

- Single acting actuators are also used mainly in the plastics industry. They are responsible for ejecting the finished parts from the plastic molds. The compressed air used in the opening phase of the valve pushes out the finished piece.

- They are also used for lifting tasks such as vehicle jacks or air-powered lifts. After compressed air passes through the opening valves, the pistons move upwards, raising the loads. Next, the mechanical springs bring the pistons back to the previous position.

Some applications for double acting pneumatic actuators include the following.

- They are used in various material handling applications, such as lifting equipment or conveyor belts. Double acting pneumatic actuators offer the most precise control of direction and force. They are the best choice for high-cycle applications.

- On the other hand, they also come in handy in robotics that require controlled and precise motion. Double acting actuator valves control robotic arms’ movement and other necessary components. They are handy in these applications because robotics rely on the movement of different components.

- They are also used in machine tools such as lathes or milling machines. Here, they control the cutting components to make the process more accurate and efficient.

Conclusion

You must assess your application’s needs and priorities when debating between single acting vs double-acting actuators. Both systems rely on compressed air as an energy source but perform differently.

It’s prudent to consider your budget when looking for the best actuator for your application. For instance, how frequently will you be performing maintenance? Do you need your actuators to be running all day? Note that single acting actuators need more maintenance than double acting actuators, so they are cheaper.

On the other hand, you need to consider replacement costs, especially for single acting actuators. Double acting actuators perform faster and more accurately but are more expensive.