You may ask how a double acting pneumatic cylinder works if you have a pneumatic system. Well, understanding pneumatic systems and their components is important to ensure the proper functioning of any pneumatic system. Let’s start by getting to know the double acting cylinder.

What is A Double Acting Pneumatic Cylinder?

As a pneumatic actuator, a double acting pneumatic cylinder relies on compressed air to generate bidirectional force. Whether extending or retracting, pneumatic cylinders convert energy found in compressed air into linear motion.

Note that single acting cylinders will exert force in only one direction, specifically extension. As the name suggests, double acting pneumatic cylinders provide bidirectional force strokes.

Double Acting Cylinder Working Principle

The double acting pneumatic cylinder working principle involves using compressed air to create linear motion. It is a controlled application that involves a bidirectional force, extension and retraction. Let’s have a look at the key stages of the double acting pneumatic cylinder working principle.

Rest Position

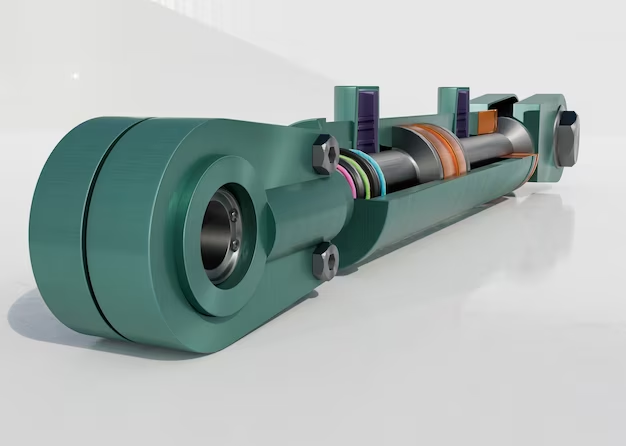

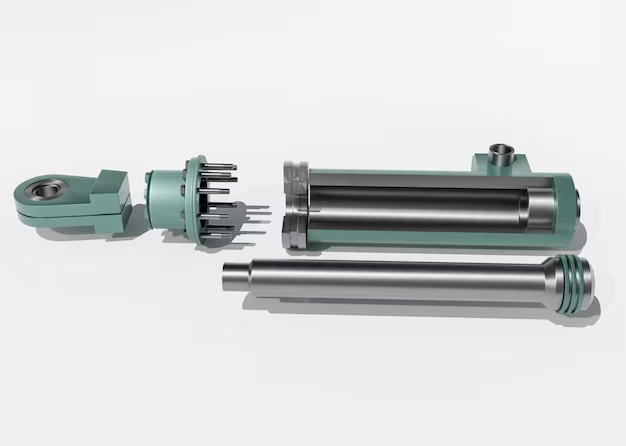

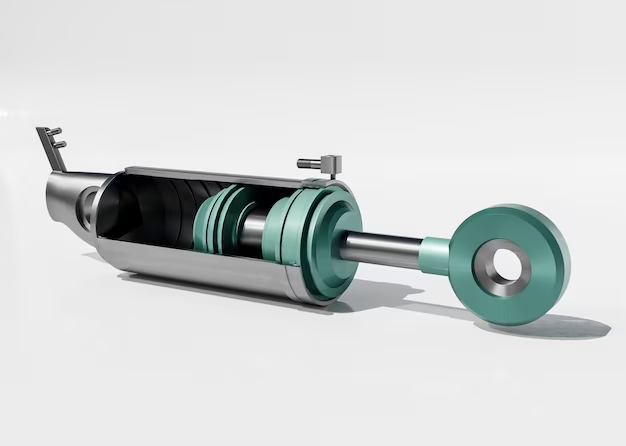

The first position of the double acting cylinder is the resting stage. During this stage, the piston is found inside the cylinder where the rod is retracted. The two chambers found on both sides of the piston contain atmospheric air.

Extension Stroke

The next stage involves initiating the extension stroke. Compressed air goes through one of the chambers through the inlet port, applying pressure on one side of the piston. As a result, there is resistance that pushes the piston outwards, together with the attached rod.

The movement forces the rod outside the cylinder, allowing it to perform the desired job effortlessly. The air on the opposite side exits through the outlet port. The process is smooth and controlled.

Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages:

There are seals in place to prevent air leakage. Additionally, they maintain the pressure differences to ensure top-notch efficiency.

Mid-stroke

During the extension process, the piston reaches the maximum level. Here, the supply of compressed air to the top chamber will come to a halt. It may also be regulated to control the piston’s speed during movement.

Retraction Stroke

The retraction process involves pulling the rod and piston back to the first stage. It happens when compressed air passes through the opposite chamber through the inlet port. The pressure allows the piston to go back in the opposite direction.

As this happens, the rod retracts back into the cylinder. On the other hand, air from the first chamber exits through the outlet port. At this stage, seals are also important during pressure regulation. They prevent air leakage and pressure differentials accordingly.

End of Stroke

After retraction, the cylinder goes back to the resting stage. Make sure there are cushioning devices in place to control the piston’s speed during each stage. It’s the best way to reduce the overall impact and delay the wear and tear.

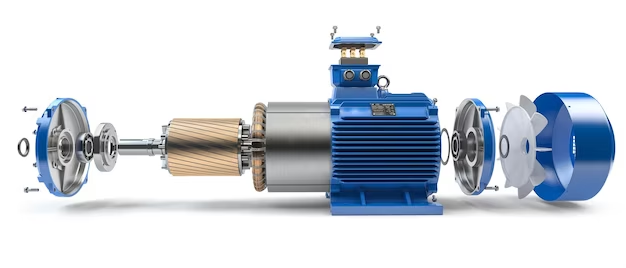

Control and Regulation

A pneumatic control system is in place for regulation and control of the entire process. It ensures that compressed air is available in the relevant chambers at all times. Additionally, it ensures repeatable and precise linear motion effortlessly.

Double Acting Cylinder Function

In any hydraulic system, you will come across a double-acting pneumatic cylinder with solenoid valve. They provide numerous functions that improve their versatility and wide application in different industries. Without going in-depth about their specific functions, let’s talk about double acting cylinder functions and roles.

Bi-Directional Actuation

Imagine having a versatile component in your system that can push and pull simultaneously. That’s exactly what a double acting cylinder does. Simply put, when you want the piston inside the cylinder to move outwards, the cylinder pushes it.

On the other hand, when you want the piston to move inwards, the cylinder pulls it. The process is unique, especially with the bi-directional force aspect. It allows the cylinder to be adapted for tasks that require back-and-forth movement.

If you want to lift something, push materials, pull objects, or hold something in place, it can be done. The cylinder acts in both directions. As such, it is versatile and applicable in numerous industrial applications.

Conversion of Fluid Energy to Mechanical Motion

Double acting pneumatic cylinders can convert fluid energy to mechanical motion. It is a special skill that allows pressurized liquid power into actual movement. The cylinder is very versatile. It makes things move by using the energy stored in pressurized fluids such as oil and water.

When fluid goes through one part of the cylinder, it will immediately become energized. This energy will be converted into a pull or push action, creating movement. It is an important function that comes in handy in various industries.

Precise Positioning

One of the key roles of double acting cylinders is precise positioning. They move where they need to be with the highest level of accuracy. If you have any machine, you may demand that a specific component is always at a specific point.

A double acting cylinder ensures that this movement is accurate, consistent and reaches the same position. Achieving accurate and recurrent linear motion is important. This allows the cylinder to handle intricate processes or anything needing meticulous alignment.

Force Generation

Double acting pneumatic cylinders have a force generation function that creates power. They act like devices that can pull or push heavy things. The strength of these cylinders comes from pressurizing one side of the cylinder, while the other one releases pressure.

It is a simple yet effective process that results in bidirectional force. The versatility of these cylinders makes them applicable to different systems. Since it’s not limited to one direction, it can exert force during extension or retraction.

Integration with Control Systems

Besides mechanical actuation, double acting cylinders also work perfectly in control systems. Here, they regulate the pressure and flow of fluid. The process allows fine-tuned control of the double-acting cylinder movement.

It is a useful integration, especially in applications requiring coordinated movements and precise adjustments. The mechanical actuation aspect and advanced control feature improve the efficiency of these cylinders in any industrial setting.

Dynamic Response

Yet another unique characteristic, double acting cylinders also showcase dynamic response. This refers to their swift reactions to pressure differentials. This feature comes in handy where fast response and agility are important.

These cylinders can respond dynamically to different conditions. As such, they can adapt quickly to any condition without compromising precision and efficiency. Simply put, these cylinders can operate in a dynamic environment seamlessly.

They can provide rapid adjustments when handling materials with different equipment. On the other hand, they provide real-time responses to changes in load. The dynamic nature of double acting cylinders allows them to provide agility in any environment effortlessly.

Controlled Movement

Finally, these cylinders can control how they move. They can adjust the speed and force of their movement without sacrificing the operation. A double acting pneumatic cylinder ensures that the piston’s movements are calculated and controlled.

Double Acting Pneumatic Cylinder Application

Due to their functions and roles, double acting pneumatic cylinders are used in various industries. They can generate controlled linear movement during extension and retraction. They are versatile and reliable.

As such, they are the most essential components in numerous industrial processes. Let’s explore double acting pneumatic cylinder applications in detail.

Manufacturing and Automation

Here, double acting cylinders play a huge role in assembly, packaging and material handling. With their controlled movement and bi-directional force features, they are used in different applications.

A double acting pneumatic cylinder symbol is found on most robotic arms, conveyor systems and other types of automated equipment. Here, they provide precise bidirectional control of linear motion. Their accuracy is unmatched and ensures 100% efficiency.

Machinery and Equipment

Double acting cylinders play a critical role in numerous industrial machines and equipment. For instance, hydraulic presses control the movement of the press ram. Here, they can guarantee accurate forming, shaping, and stamping.

Additionally, they are used in lifting, clamping, pulling or pushing machines. Here, they can guarantee top-notch accuracy and efficiency in all processes.

Construction and Earthmoving Equipment

If you have come across construction equipment such as loaders and excavators, you must have seen how they work. Well, double acting cylinders have a role to play too. They control the extraction and retraction of the equipment.

When the booms and buckets move up, out or down, double acting cylinders aid in this process. As such, they contribute greatly to the function of construction and earthmoving equipment.

Agricultural Machinery

Double acting cylinders also have a role to play in the food we eat. They are found in tractors and other agricultural equipment for many functions. For instance, double acting cylinders raise and lower specific components of these machines.

On the other hand, they also help with adjusting equipment positions. Double acting cylinders also control the operation of attachments such as seeders and ploughs.

Aerospace Industry

Double acting cylinders are used in aircraft systems. They are used in the extension and retraction of landing gear components and mechanisms. They also contribute to the operation of control surfaces. This improves the maneuverability of aircraft.

Automotive Manufacturing

Automotive assembly also involves the use of double acting cylinders. They are used in processes such as material transfer, welding and positioning. The cylinders improve the speed of the manufacturing process.

They also play a key role in improving the overall efficiency of the automotive manufacturing process. All repeatable movements are accurate and unique, thanks to double acting pneumatic cylinders.

Material Processing and Handling

Any industry with processes such as lifting, sorting and conveying, relies on double acting cylinders. As such, they come in handy in material processing and handling industries. These cylinders are used in conveyor systems to move products in the assembly line effortlessly.

Medical Equipment

Diagnostic machinery, surgical tables and hospital beds use double acting pneumatic cylinders. Extensions, retractions, lifting and lowering of any equipment requiring precise movements need these cylinders. As such, double acting cylinders ensure precise positioning and adjustment.

Conclusion

Double acting pneumatic cylinders function by converting energy found in compressed air into linear motion. One of the unique features is creating bidirectional force, especially extension and retractions.

They are used in many types of equipment, including medical equipment, aircraft, construction machines, conveyor belts, etc. In any of these industries, these cylinders work through controlled movements, precision movement, force generation, etc.

These cylinders are versatile, efficient and improve overall output for any machine. Whether they are pulling or pushing, double acting pneumatic cylinders are applicable in numerous industries.