Pneumatic equipment plays a crucial role in the present world; it enables the production of devices that use air under pressure (or other gas) to perform various tasks. The list in this article is an overview of these devices, what they do, and their most common applications. Let’s begin with the definition.

What is Pneumatic Equipment?

Pneumatic equipment is any device that relies on a compressed gas, typically air, to work — or is part of a system that depends on pressurized gas to perform a task. It can be an actuator in an industrial system, a stamping press, a lifting mechanism, or a robotic gripper.

This equipment finds helpful applications in the manufacturing industry, where it controls various processes. The technology also finds use in other systems and settings:

In the construction industry, pneumatic tools and equipment serve various functions, from hoisting to pressing. In the automotive world, air systems operate brakes, valves, and lifters; the list is almost endless.

Resource: https://www.designworldonline.com

Pneumatic Equipment Advantages

When a mechanical device doesn’t use air, it’s either hydraulic or electric. All these options have advantages and disadvantages. Below is a list of benefits that make pneumatic equipment a better choice.

- Simple Construction: it has a simple design consisting of valves, tubes, and a motion-producing device. That makes it less challenging to manufacture or use.

- Easy Maintenance: air systems rarely fail. They also wear slowly and do not need frequent part replacements. Their simple construction makes them straightforward to repair.

- Enhanced Safety: air is an inactive material. Air-based equipment will, therefore, not cause explosions around flammable materials or pollute the environment. It does not overheat or cause a shock risk.

- Low Cost: save for the cost of pressurizing air, these systems are economical to acquire and maintain.

Given these benefits, air-operated systems are available in many designs for varied uses. Below is a list of these pneumatic equipment examples and their functions.

Resource: https://www.packworld.com

Pneumatic Equipment List

A good number of devices utilize air to work. We compiled a list of these devices. The list covers products that pneumatic equipment manufacturers may produce and supply, from actuator cylinders to fittings for air-operated systems.

1. Pneumatic Cylinders

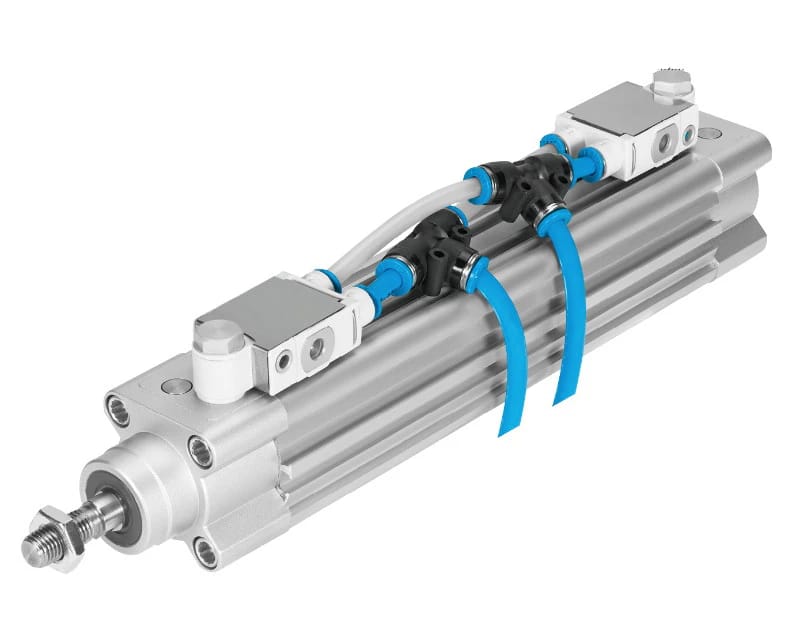

This cylinder is an air-tight barrel with a piston inside. The piston moves under the action of compressed air that enters through an inlet port. At the end of the stroke, the air exhausts to the outside, and the cycle can repeat.

By harnessing the motion of the piston, the barrel is can operate a mechanism. This working principle is the idea behind air actuators. The device finds use in any applications:

You can use it to operate a lifting system, move an object, or hold it in position. These are popular in industrial settings, forming a part of automation devices and systems.

2. Pneumatic Actuators

This actuator is an air-operated motion device used to cause movement for process control, positioning, and other motion-related tasks. Its mechanism can be in various configurations:

It can be a piston in which compressed gas moves back and forth, a vane (s) in an enclosure, or a flexible diaphragm that moves under air pressure. It can also be a rack/pinion system connected to a piston.

Air actuators have varied applications. You can use them for valve control, material handling, and in manufacturing plants to automate packaging. In robotics, they change the force of compressed air to movements.

3. Pneumatic Valves

This valve type uses compressed gas to throttle flow or operate its on/off mechanism. For instance, it can be a mechanism that pushes a diaphragm up and down, a vane that rotates on a shaft, a piston inside a cylinder, etc.

You can use this mechanism to automatically regulate the flow of various fluids, such as water, oil, steam, industrial chemicals, and different gases, including air. The types of valves you can control vary from ball valves to globe valves.

Using air makes the flow control safer and more reliable, and other benefits include fast action, simple construction, and cost-effectiveness.

4. Pneumatic Tubes

The pneumatic equipment list also includes the little-known-about transportation tubes that move items from one point to another using air pressure.

A typical system of this type comprises carrier capsules to hold the item, sending and receiver stations, and blowers to create the pressure difference.

These tubes are mainly used in warehouses, manufacturing plants, and by logistic companies. In banks and offices, they help workers exchange documents and cash. Hospitals and other health facilities use them to transport drugs, samples, etc.

5. Pneumatic Fittings

Pneumatic machinery and equipment require connection components called fittings. The fittings act as leak-free joints, linking the tubing to other device components such as cylinders.

Different types of these fittings are used based on their material, construction, and installation methods. They include threaded fittings, compression fittings, and push-to-connect fittings.

Different fittings can also handle varying amounts of fluid pressure or fit various hoses and tubes. These variations include the materials used to make them, such as plastic, aluminum, steel, and brass.

6. Pneumatic Grippers

They convert the force of a pressurized gaseous fluid into a gripping force. They consist of valves to regulate airflow, mechanisms to produce motion, and the gripper (the part that makes contact with objects).

Air-operated grippers are part of many automation processes, especially in manufacturing. They execute pick-and-place operations and are common in assembly or packaging systems.

These grippers offer the advantage of fast action, immense holding force, and safety in many environments, including flammable materials and other hazardous conditions.

7. Pneumatic Conveyors

Pneumatic conveying equipment moves dry materials through a pipeline by pumping air into it. The materials may be powders or larger particles.

Practical uses of these conveyance systems include transporting non-food materials like plastic granules, sand, and cement or food-based powders such as sugar, salt, oats, and dry milk.

They transfer products safely and efficiently without loss or damage. They are also low-cost systems that offer an economical way of handling and transporting products in the manufacturing industry.

8. Pneumatic Presses

This pneumatic industrial equipment utilizes compressed gas to produce motion and force. It then uses the force to move one workpiece toward another, making it perform a pressing task.

It consists of a compressed air source, a cylinder to receive the air, and a piston/plunger assembly to transfer the air pressure to the workstation or pressing tool.

The tasks you can use these presses to accomplish include stamping, punching, pressing, and material forming. Options include benchtop machines for smaller tasks and vast presses for industrial processes.

9. Pneumatic Lifters

Pneumatic lifting equipment elevates loads from low to higher levels and vice versa. It employs a simple technology that consists of a hoisting mechanism composed of a piston moving inside a hollow cylinder.

Its applications include lifting and lowering loads. Typical usage environments range from manufacturing facilities and warehouses to workshops. It also makes car lifts, elevators, and airplane flap lifters.

These lifters offer the advantage of being efficient, effective, and operable in many environments, including harsh conditions or flammable materials.

Conclusion

The pneumatic equipment list in this article has devices that depend on gas under pressure to work. Using them provides several benefits, including efficiency, reliability, safety, and cost-effectiveness. Air-operated systems are also versatile. You can use them in various applications, from industrial automation to everyday tasks like opening gates.