Pneumatic tube systems, invented in the late 1800s, are now essential to many fields. These tubes move cylinder-shaped containers using air pressure through a tube network. In this article, we will explore how pneumatic tube systems work. We will also learn more about their uses and applications.

What is a Pneumatic Tube System?

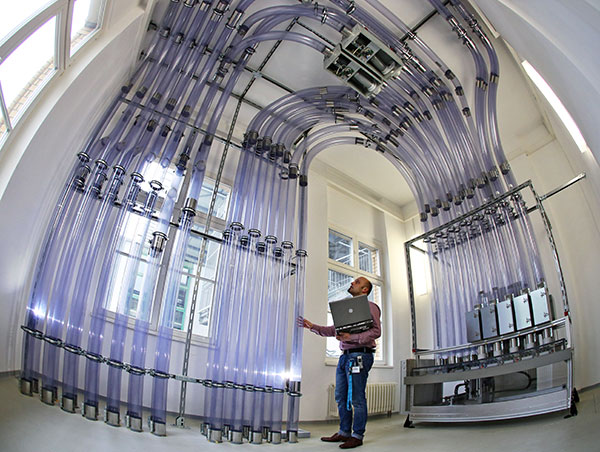

A pneumatic tube system consists of tubes transporting capsules using an air compressor. It transports small items, such as documents, within a building. The transport system is mostly used in places that need fast and efficient delivery.

It is made up of the following components for efficient delivery.

- A Tube Network – For this delivery system to work, a network of tubes must be installed throughout the building. It connects to various locations or stations.

- Pneumatic Tube Canisters or Capsules – All items must be placed in the capsules or pneumatic canisters. They are airtight to allow efficient transport through the system.

- Air Pressure/Vacuum – For the system to work, there must be compressed air or a partial vacuum. This propels the capsules through the tube system.

- Control Systems – Every system must have a control system. It is used to manage the flow of pneumatic tube canisters and direct them to their destinations. You must input information at the terminal when sending anything using this system.

- Arrival and Dispatch Stations – The system includes arrival and dispatch stations with loading and unloading systems. These allow the capsules to enter and exit as needed. You can load capsules at the dispatch stations for them to arrive at the final destination.

Over the years, a lot of industries have now adopted the use of these tube systems. They are beneficial for their speed and reliability for moving small items over short distances. These systems are needed where timely delivery of materials is critical.

How Do Pneumatic Tubes Work?

Using compressed air or a partial vacuum, the tubes can propel capsules from one station to another. Let’s look at a step-by-step guide to how pneumatic tubes work.

Capsule Loading and Dispatching

First, you must load a capsule with the item you are dispatching. Capsules are airtight to allow proper movement within the tube. Ensure the capsule is locked properly before being in the dispatch station. Also, your capsule must have the right destination information.

Routing, Switching and Propulsion

The control system comes with switches and routing logic. It determines the right path for the capsule depending on your dispatch instructions. The tube system has switches to redirect capsules through different tubes. How do pneumatic tubes turn corners? Well, that’s where the switches come in handy.

As such, a capsule can navigate the tubes carefully to arrive at the destination. On the other hand, if your system uses compressed air, the air is placed behind the capsule. This way, it can move through the tube to arrive at the destination.

If your complex system relies on a partial vacuum, a vacuum pump will create low pressure in front of the capsule. The atmospheric pressure is responsible for pushing the capsule forward.

Tube Network, Arrival and Output Interface

A tube network connects various destinations within a facility. Switches are installed within the tube network to ensure capsules reach their destinations effectively. The arrival stations have unloading mechanisms to release the capsules safely.

Furthermore, there is an output interface at the destination for notifications that the capsules have reached safely. You can pick up the capsule at the arrival station. The pneumatic tube transport system can be installed in industrial or commercial settings.

Safety and Control Features

The system has additional safety features like emergency stops and sensors. These diagnose and address issues such as blockages or capsule jams. Additionally, the control system is used to manage the whole process.

The control system coordinates the capsules’ loading, routing, propulsing, and unloading processes. You may interact with the control system through the terminal stations. Here, you must provide information about the destination.

Pneumatic Tube Advantage

These tubes are beneficial in many applications. Let’s look at the benefits of having these tube systems in your facility.

Speed, Efficiency and Reliability

The systems provide efficient and speedy transportation of small items from one point to the other. They are also renowned for their reliability. There is a reduced chance of errors or delays unless there is a system failure.

Security and Reduced Human Error

The system improves overall security for all items being transported. Usually, it is a closed and controlled environment. It comes in handy in facilities such as hospitals or financial institutions. Notably, the system is automated, thereby reducing human error.

Improved Productivity and Cost-Effectiveness

These tube systems allow small organizations to improve overall productivity. In fact, employees no longer have to move items from one location to the other. They are able to focus on different tasks that boost their productivity.

In the long run, these transportation systems are very effective. The installation process may be costly initially, but it leads to reduced labor costs and savings in the long run.

Use of Pneumatic Tube System

Due to their versatility, these transport systems are used in various industries. Let’s look at the various applications of our tube systems.

Healthcare Applications

In a healthcare setting, these systems can transport medical samples. They can be moved from collection points to testing labs efficiently. Additionally, they are used for delivering medication from one department to the other.

Financial Institutions and Retail Industry Applications

In these industries, the transport systems transfer cash from teller stations or cash handling areas. Additionally, they are used to transfer documents or paperwork from one station to another.

Industrial and Manufacturing Applications

In any industrial and manufacturing facility, there is a lot of transportation of tools and small parts. This tube system can move these from one production area to the other.

On the other hand, they can be used to transfer samples for quality control testing within the facility. Consequently, it’s easier to improve productivity with such a reliable transportation system within the facility.

Office Environments

In an office, the tube network transfers documents, files, and paperwork. They can be moved between different departments or floors within the building. It beats the need for people to move between different floors.

These systems also come in handy for mail distribution in a normal office setting. You must be able to receive your mail within the fastest time possible. Nevertheless, it’s much better than a mailroom intern moving between floors delivering mail.

Libraries

Libraries are categorized into different sections. With books being too heavy, having such a transport system makes movement easier. You can use this system to return or distribute books within any section.

Pharmacies

Dispensing prescription medication inside a pharmacy is easier, thanks to our tube systems. The pill bottles can be passed through the capsules from the stocking room to the teller. As such, your customers don’t have to wait too long to receive their medication.

Casinos and Gambling Institutions

In casinos and other gambling institutions, the transportation of chips for games needs a lot of security. This complex system plays a huge role in the transportation of chips. Furthermore, if additional chips are needed on the floor, the network of tubes can transport them effortlessly,

Distribution Centres

With the dramatic increase in ordering applications, this transport system benefits distribution centers immensely. With such a system, you can quickly dispatch orders from the packing to the shipping area.

There is no need to physically pick up each order with such a system in place. The machine can send new orders to the packing area as they come in. It’s the best way to improve productivity in this setting.

Homes

Are these systems still used in residential settings? Well, pneumatic tube systems for home use are quite rare. Yet, it’s an option you can utilize in your house if you like it. However, you’ll have to think about certain things to get it functioning. Think about it: you need ample room and the right setup to put in the pipes.

Plus, the tubes’ use and their real value in your home is essential to consider. If your house is big and has many rooms, this could be very useful. Small homes may not find it practical to have this system. Considering the cost of installation and maintenance, it might be a little steep for a smaller budget.

Let’s not forget a lot of upkeep is required for these systems to function efficiently. Beware, costs can stack up without careful attention. These systems are often noisy in operation, which may disrupt a quiet home. Right now, tube systems are more common in commercial settings than in homes.

Conclusion

To sum it up, pneumatic tubes use compressed air or partial vacuums. They move small items in canisters from one area to another. They are beneficial for their speed and reliability in different settings. They rack a lot of benefits over the years, including improved productivity and fast delivery of items.

As a professional pneumatic tubing manufacturer, we are committed to providing the highest quality pneumatic tubing to ensure your system runs more efficiently and stably.