Pneumatic actuators use a one-way or two-way mechanism to turn air pressure energy into motion. Below, we compare the types of this component: single-acting vs. double-acting pneumatic cylinder. Learn everything about their differences, pros and cons, and typical uses in the automation sector and other industries.

What is a Single Acting Pneumatic Cylinder?

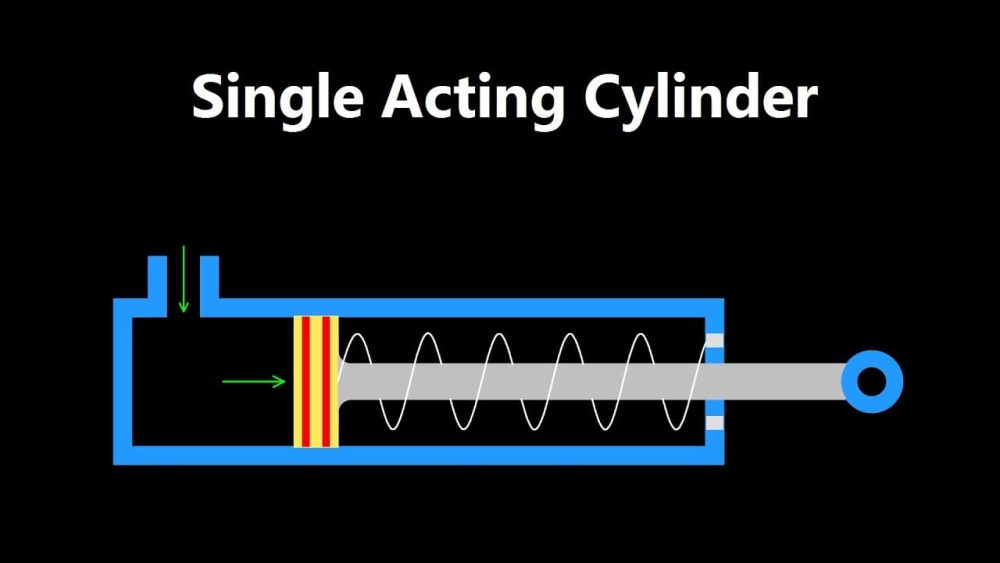

A single-direction cylinder only uses air pressure to move the piston in one direction. In other words, it only has one working or compressed air stroke. For the reverse motion, it relies on the action of an external force. On most cylinders of this type, this force is a return spring.

The one-way type is usually either a pull or push style. The pull version retracts the load into the barrel every time it receives compressed air pulling the load. The push type does the opposite. It extends the rod in the working stroke and retracts it when air pressure reduces behind the piston.

What is a Double Acting Pneumatic Cylinder?

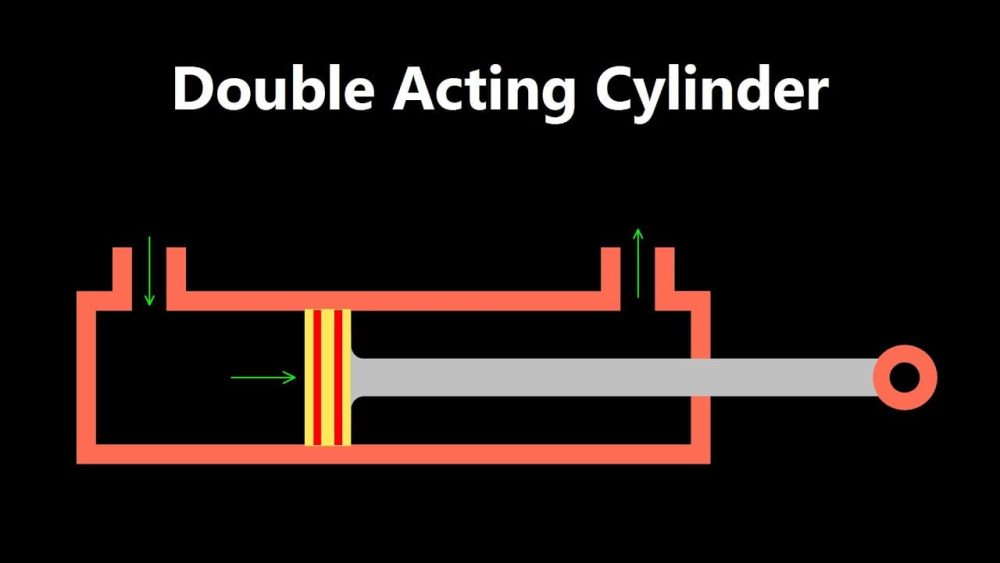

A dual-action air cylinder uses air pressure for both forward motion and retraction. It receives compressed air on either side of the piston surface to achieve that. During operation, the piston extends the rod to push the load and retracts to pull it.

The bidirectional cylinder is a more complex design. It also requires more air for the two working strokes since both forward and return strokes are powered movements. However, it offers more control than the one-way type, among other variations, as explained next.

Resource: https://youtu.be/ClOXkkVDIiY?

Single Acting vs. Double Acting Pneumatic Cylinder

The difference between single-acting and double-acting pneumatic cylinders exists in their design or construction, working principle, and application specifics.

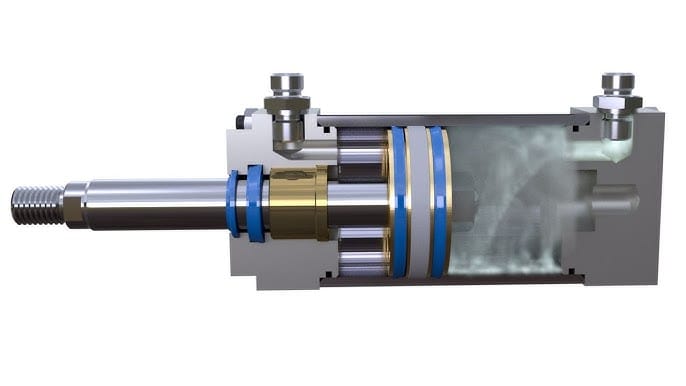

Construction

The one-way barrel has a single opening for compressed air, which works as an inlet as the exhaust port. It also typically has a return spring to retract the piston. The spring connects to the movable piston and rod assembly.

Instead of a spring, the two-way type uses air pressure to move the piston forward and backward and has two compressed air inlets. It has a more complex design than the single-direction version.

Working Principle

Compressed air enters a one-way barrel from one side, pushing the piston forward or retracting it and moving a load. At the end of the stroke, the air supply cuts off, the pressure reduces, and a spring or other force pulls the piston back.

The bidirectional design lets air on one side of the cylinder, pushing the piston forward. Compressed air enters on the opposite side and forces the piston back. This action action means two working strokes, making the motion more controllable.

Application

Application differences characterize the single and double-direction cylinder types, given their varied design and operation. Single-direction devices are typically suitable for the following actions:

- Air-operated lifting equipment in industrial environments

- Clamping tools such as those used in carpentry and similar applications

- Ejection systems in the manufacturing industry

- Positioning equipment in industrial systems

- Assembly tasks with lighter loads

- In consumer appliances

The bidirectional types offer greater precision and control. As a result, they find applications in the automation industry. Example uses include:

- Robotics to offer controlled movements

- Industrial process systems where it’s necessary to move loads precisely

- Pneumatic tools that require great accuracy to operate

- Manufacturing systems that require the device to move heavier loads

- Car sprayers and washing systems

- Gate opening and closing

- Industrial valve actuators

Resource: https://youtu.be/-5w0DeteSD0?

Single Acting Pneumatic Cylinder Advantages and Disadvantages

A one-direction type offers several benefits; its downsides make it more suitable for some applications than others. This section explains these good and bad sides.

Advantages

- It has a more straightforward design and is less expensive and easier to maintain

- It uses less air, which reduces the operating costs

- The return spring provides a fail-safe mechanism in the event of air pressure or power loss

Disadvantages

- With no controlled retraction, it offers reduced precision

- The return spring is prone to wear over time, causing operation problems

Resource: https://youtu.be/v11uV96rORY?

Double Acting Air Cylinder Advantages and Disadvantages

The double-action version offers various advantages when used in many applications. Like the single-direction type, it has its drawbacks, as listed below.

Advantages

- Its precision level is way higher, with the forward and backward motion pressure-controlled

- These devices offer faster retraction speeds

- It has more robust and consistent strokes

- The forward and backward motion is easily varied, allowing greater control of tasks.

- Suitable for tasks that require both pull and push actions

Disadvantages

- It uses a complex design and operation, making it more demanding to maintain

- It requires more air and a more complicated control valve, costing more to use

- In case of a power or air pressure loss, the piston cannot return to the fail-safe position

Resource: https://www.youtube.com/watch?v=waj4kGsaFbg

Single Acting or Double Acting Cylinder?

It depends on the intended use or application. Each device type has pros and cons based on the applied use. These should form the basis of your selection.

The two-way version is your best option if the application requires greater motion control and precise load movement or if the task requires powered retraction or long strokes.

These barrel types also fit situations where speed is a necessity. Examples include pneumatic tools and various industrial processes.

On the other hand, straightforward tasks require a single-action cylinder; it’s a less expensive choice, and the controlled retraction is unnecessary. It also suits tasks where safety concerns require a fail-safe piston position or if space is limited.

Conclusion

Despite being air-operated devices, single-acting and double-acting pneumatic cylinders differ in construction and working principles. As a result, they offer varied benefits and suit different automation tasks. A single-action type is less precise but inexpensive and more economical to operate. The dual-motion style has more control but costs more.