Hydraulics and pneumatics play a crucial role in many different applications today, from industrial processes to stand-alone devices that rely on the power of a fluid to work. But what do the two terms mean and how are they different? This comprehensive guide delves into the world of hydraulic and pneumatic systems, explaining everything you need to know about their working and use.

What is Hydraulics and Pneumatics?

By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Pneumatics, on the other hand, is used for mechanisms that rely on a gas to perform the same function.

Typically, the fluid in both hydraulic and pneumatic systems is pressurized to store energy. The stored energy, and depending on the required function, can then be used to perform one of the following tasks:

- Raise a load

- Power a device

- Work a lever

- Create a push

- For traction, and

- In a wide range of automation processes

A hydraulic or pneumatic mechanism can also be a small device that you hold in the palm of your hand, or a large installation that can move extremely large loads. After their meaning, let’s now see how hydraulic and air-operated systems end up producing motion.

Resource: https://www.researchgate.net

How Do Hydraulic and Pneumatic Systems Work?

Hydraulic and pneumatic systems work by using pressurized fluids to transmit power or force. This normally involves forcing the fluid through various components to make it perform a useful function. To put that into perspective, here’s more about using fluids to transfer force.

Principles of Hydraulics and Pneumatics

The working of hydraulics and pneumatics is based on the principle of pressure transmission in fluids (liquids and gases). When a fluid is confined to a space and pressurized, the force it exerts spreads in all directions.

Consequently, this force can be controlled (or multiplied) and used to create linear or rotary motion. This can then be used to press things or carry out any other process. Power transmission using fluid offers these benefits:

- High power to weight ratio, especially when using liquids

- Spark-free power transmission

- No overheating problems, unlike electric systems

- Ability to support multifunctional control actions

- Reduced machine complexity with no gears and chains or belts

- Smooth operation that’s free from vibrations

- Reduced parts wear

- Quiet parts when using liquids like oil

Examples of Hydraulics and Pneumatics

Today, hydraulic and pneumatic devices are being used in virtually every industry. This can range from simple devices that use a single, linear actuator to large multi-actuation systems. Common examples for each method of transmitting fluid force are listed below:

Hydraulics Examples: industrial automation and other systems, heavy-duty lifts, excavation equipment, automotive braking and steering components, aircraft parts, and other systems where large forces and higher working precision levels are necessary requirements.

Pneumatics Examples: industrial actuators to move or hold products, power tools like air hammers and pneumatic drills or wrenches, actuators for switching electrical circuits, and other light applications that require fast-acting and safe or clean mechanisms.

Resource: https://www.youtube.com/watch?app=desktop&v=o7OKhjfTgPo

Hydraulics vs. Pneumatics

Both hydraulics and pneumatics rely on the power of pressurized fluids to work. But there are also notable differences between the two, and these should inform your decision when making a choice for your project. With that in mind, here are differences and similarities between hydraulics and pneumatics in more detail.

Similarities between Hydraulics and Pneumatics

Hydraulic and pneumatic systems are similar in a few ways. First, they harness the power of compressed fluids. In other words, both systems are fluid-based and identical in their working principle.

Another similarity is that, in order to work, both systems require the use of various identical components: parts to exert pressure on the fluid, those that prepare and convey the fluid, valves to control the flow, and actuators to turn the flow into mechanical energy.

In terms of application, systems that rely on hydraulics and pneumatics are used in many similar settings, with both offering almost identical advantages. These include manufacturing, construction, automotive, and so on.

Hydraulics and Pneumatics Difference

Despite their reliance on fluid power to produce motion, there are notable differences between the two systems. The main difference between hydraulics and pneumatics is the type of fluid (or medium) that each uses to transfer power.

Hydraulic means a liquid is being used. This is mostly petroleum-based oil or even water. These liquids are barely compressible, which means their volume will not noticeably change when pressurized. The result is that their pressure can increase tremendously with the application of force.

On the other hand, pneumatic systems rely on compressed gas (such air or an inert gas like nitrogen) to work. Unlike the fluids used in liquid-based systems, air is compressible. Despite offering quicker movements, that means less power when compared to a fluid based system. It also means less precision.

Resource: https://www.youtube.com/watch?kG_sLBr1vwo

Hydraulics or Pneumatics?

The question whether to use hydraulics or pneumatics depends on various factors. Mostly, the requirements of the application in terms of load, required speed, cost, load amount, precision level, and other considerations dictate the type of technology to use.

Pneumatic Systems

- Air-operated systems are best suited for applications that require a high level of cleanliness or sanitation. That’s because they’re not prone to spills.

- Air is also freely available and doesn’t cost anything, which makes pneumatics a more cost effective option.

- A pneumatic device will also not need storage for used fluid, since the gas can be safely exhausted into the air.

- Hydraulic systems are slow. If your application requires fact-acting actuators, pneumatics would be your best choice.

- These systems are also lighter and can be made into very small products or devices

- You can safely use pneumatics in environments that contain sparks are susceptible to fires, such electrical systems.

Hydraulic Systems

- If large loads are to be moved, your project would greatly benefits from the immense power of hydraulics.

- For higher operating accuracy, hydraulics is the better option.

- If quiet operation is needed, too, since these systems are almost silent.

- However, hydraulics systems are also bulkier, plus they need more frequent maintenance.

Resource: https://www.designworldonline.com

Hydraulics and Pneumatics Applications

The applications of hydraulics and pneumatics are wide and varied. In other words, their use is almost limitless. Here, we’ve only listed some of the most common of these uses today.

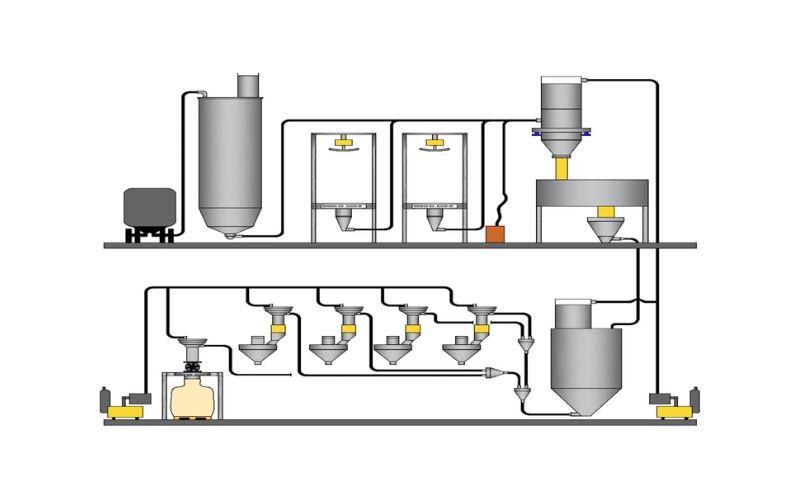

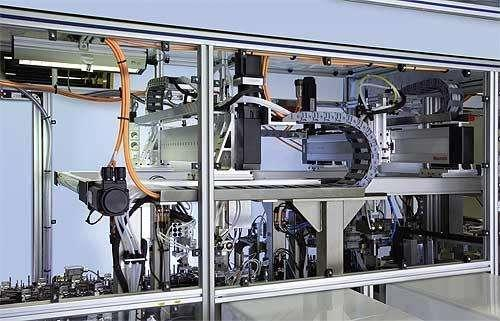

1. Manufacturing Industry: hydraulic and gas-operated systems are used to execute different industrial processes, from those that require simple actuators to those that involve complex automation.

2. Power Tools: today, hydraulic and pneumatic tools make tasks easier to carry out. These include power tools like pneumatic drills and hammers or air motors.

3. Automotive Applications: in the automotive sector, hydraulic and pneumatic circuits form the basis of many systems, from brakes and shocks to steering mechanisms.

4. Mining and Construction: the mining and construction industry benefits from the use hydraulic systems. These are commonly seen in heavy-duty machines such as excavation equipment.

5. Aerospace: hydraulics and pneumatics help perform important functions in aircraft systems, from landing gear and brakes to other systems.

Conclusion

Hydraulics and pneumatics are popular technologies today. Each type has its place in different industries, based on the required function. When selecting whether to use a fluid or air-operated system, one must understand the advantages and limitations of each. We believe this article has provided you with in-depth information about the two technologies, including their many uses.