Pneumatic components represent one of the most used technologies today, with their application ranging from the automated systems of different industries to individual tools. In this overview, we take a more detailed look at the different components of pneumatic systems, how they work, and their most common applications.

What are Pneumatic Components?

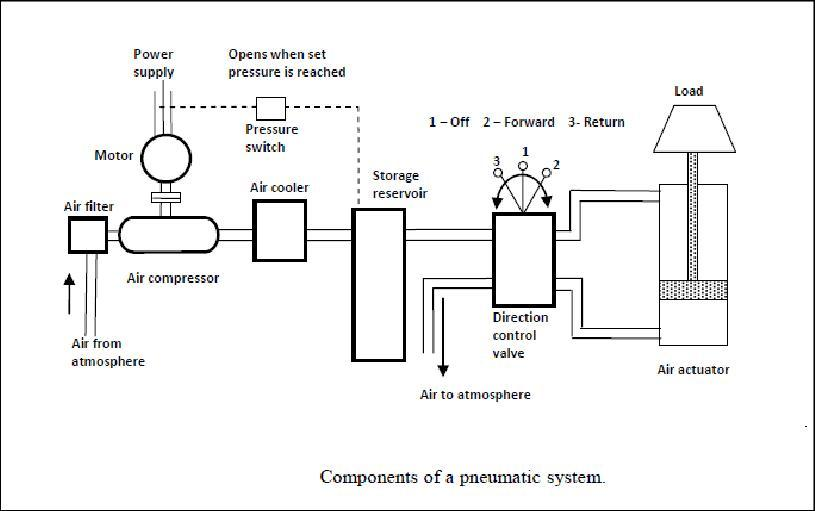

Pneumatic components mean the replaceable parts that make up a pneumatic system or device. In other words, they are components that take air from the atmosphere, compress clean and it, and then direct it—through a controlled opening—to an actuator to generate motion.

Before we can see what these pneumatic system components are and what they do, here is a brief introduction to the operation of air-based systems. This will give you an overview of what’s involved in each stage of the process, and help you understand the function of each part better.

Working Principle of Pneumatic System

Pneumatic systems operate on the principle of pressurized air exerting and transmitting force. When a gas is confined to a space under intense pressure, it stores energy. Using clever mechanisms, this force can be controlled and transferred to do useful work. Here’s what basically happens:

- A compressor extracts air from the atmosphere and stores it in a reservoir or air storage tank.

- From here, the air is fed, via tubes, to what’s called an air separation and preparation unit.

- This unit comprises these different parts: separator, filter, regulator, and lubricator.

- The separator, using centrifugal force, removes moisture from the air, while the filter extracts any particulates and other debris.

- The regulator adjusts the air pressure. The lubricator, on the other hand, adds some lubricant to air before it can go to the next stage.

- Clean and dry, the compressed air now enters the inlet of a directional valve.

- From here, it enters various ports in on its way to the actuator where it will be used to produce motion.

- The actuator is often a piston mounted inside a cylinder to generate motion from the compressed air. The actuator can also be a vane mechanism or diaphragm.

Components of a Pneumatic System

The pneumatic sequence above requires the action of various parts. These make what’s called a pneumatic system or equipment and device. The parts include the following—note that this pneumatic components list represents the main parts.

- Compressor and air storage tank

- The air preparation unit (FRL) that’s composed of a filter, regulator and (most often), a lubricator

- Fittings to connect valves and other parts

- Tubes to transport the air

- Valves to direct air to the actuator in a controlled way

- The actuator which is often a piston and cylinder mechanism. Others include turbines and diaphragms

Resource: https://www.youtube.com/watch?w1XN_Gdk65Y

Where is Pneumatics Used?

Pneumatic systems are used in a broad range of applications, given their versatility and ease of use. Most commonly, they form the basis of industrial equipment and the automated processes of different industries such as manufacturing, oil and gas, power generation, and so on.

For example, various pneumatic components are used to operate the robotic arms of automation equipment to move, sort, assemble, or hold products in place. They also find application in the safety systems of these facilities, and may even be used to remotely switch electrical systems.

There are many reasons why pneumatic components and systems are preferred. Air, being free and readily available, makes them easy and cheaper to run. Air-operated machines also operate with no risk of fires or explosions. That’s in addition to being clean and suitable for use in food and beverage, pharmaceuticals, and the electrical or electronics industry.

Resource: https://www.researchgate.net

Pneumatic System Components and Their Function

Now that you understand the applications of pneumatics, let’s take a look at parts that such systems are composed of. These range from the compressor that initially draws air from the atmosphere, to the actuator that converts the transmitted force into motion. Here is a list of the main pneumatic components and their functions.

1. Pneumatic Compressors

Pneumatic compressors take air from the surrounding space and compress it into a smaller pace. The compressed air then contains stored energy. This energy is used by the pneumatic system to do useful work. Most often, the compressor stores the compressed air in a storage tank or reservoir.

2. Air Separator Units

These are components of pneumatic systems that help separate water (moisture) from the already compressed air. They basically consist of vanes that rapidly spin the air around. The centrifugal force that the spinning vanes generate causes the air to shed moisture, which can then be easily removed.

3. Pneumatic Filters

The air entering the system from the compressor may contain impurities. These could end up clogging the system over time. The work of pneumatic filters is to sieve them out. To achieve that, the filter uses a two stage system consisting of vanes and a filtration element. The vanes spin the air around, while the element acts as the sieve to remove debris.

4. Pneumatic Regulators

Just as their name indicates, these pneumatic components adjust the flow of air as it goes into the system. The typical pneumatic regulator is a spring loaded unit that, using a variable valve, increases or decreases the airflow as required.

An increase means more power being transmitted to the actuator, while decreased airflow means the opposite. A pressure gauge is also often added to the regulator. This allows the system’s operator ensure the proper control of its operation.

5. Pneumatic Lubricators

Sometimes, and depending on the type of system or machinery, a lubricator is one of the components of pneumatic systems. This is commonly seen in air motors and power tools that use pneumatics to work.

The part sprays lubricant into the compressed air coming out of the separator unit, which helps lubricate the different moving parts of the system to reduce friction.

6. Pneumatic valves

In order to properly direct air and perform the required function, pneumatic components include directional valves. These serve to control airflow and pressure inside a pneumatic system and consist of an array of pathways that can open or close as needed. Pneumatic valves can be different types such as:

- Hand operated valves

- Foot valves

- Palm operated valves

- Pushbutton valves

- Solenoid operated valve

Most often, pneumatic valves are solenoid operated. The solenoid works a plunger that, in turn, regulates the flow of air to achieve the desired function. With

7. Pneumatic Cylinders

These pneumatic system parts house the piston that moves to convert air power into motion. Pneumatic cylinders are fed by tubes that deliver compressed air or other gas into them. Inside the cylinder, a piston moves back and forth to create motion.

A pneumatic cylinder can be a single action or double acting type. Single acting cylinders use compressed air to push the piston one way only, and often include a return spring to pull it back. Double acting cylinders can push the piston back and forth.

8. Pneumatic Actuators

Pneumatic actuators are parts that move under the action of compressed air to do useful work. This can be linear motion to move or clamp a load, or it can be rotary motion to operate a valve or other action and process.

Most actuators are cylinder-based. These consist of a piston that can move inside a cylinder. The cylinder receives compressed air from the directional valve. The energy of the air then causes the piston to move and operate a required system or device.

9. Pneumatic Fittings

Fittings serve to join the different pneumatic system components together, the valves to be specific. They help prevent the air from leaking out, which makes them important pneumatic circuit components. In addition to fittings, other essential components include the tubes that help carry compressed air from one part of the system to another.

Conclusion

Different pneumatic system components perform different functions in air-operated systems, enabling the transmission of fluid power in different industrial processes and power tools or other devices. Depending on the required function, these can be automation equipment, power tools, and so on.